The Difference Between a Main Panel and Subpanel, and How to Use Them

September 13, 2021

A main panel is an installed box where the power from the utility company enters the premises. A subpanel is an installed features that acts as a middle ground for the main panel and other types of circuits that are connected to your property. In this brief guide, Hardcore Electric will provide you with information pertaining to main panels and subpanels and instruct on their usage.

WHAT IS THE MAIN PANEL?

As mentioned previously, this is a panel where the power comes in from the electric company. It typically includes a main switch that allows for the power to be connected and disconnected.

In most instances, it also includes the subpanels associated with the premises. It provides power, controls power, and regulates the power. It is possible to have up to six breakers to control subpanels and other circuits; however, most main panels have one main breaker.

Many may have a fused disconnector that may be pulled out instead.

WHAT IS A SUBPANEL?

The subpanel acts as a type of intermediary between circuits that are part of the property and the main panel. These connect directly through a special type of circuit feeder and include a breaker at either end. These may include additional subpanels. These are very similar to the main panel; however, they are unable to push more power in an independent manner. Instead, they receive electricity from the main panel on the property.

ARE SUBPANELS NEEDED?

Yes, there are many advantages to having subpanels. These include the following:

- 1. By adding subpanels, you have the ability to separate circuits so that your business may operate in the most efficient manner possible. This helps in the easy identification of switches and also offers many benefits – in terms of electrical maintenance and/or electrical repairs that become necessary.

- 2. Main panels are usually placed inside of a business. Subpanels may be placed anywhere. This actually aids in providing a boost to the safety of your business. If a fire or other emergency occurs, you can quickly turn off the subpanels if they are outside of the building to avoid injury, increased severity of the fire, and/or to prevent electrocution.

- 3. Subpanels allow you to safely add extra circuits without compromising the limitations of the main panel. These also allow the power to be evenly distributed throughout the property so that there is no too much of an electrical load on any one area.

HOW TO CHOOSE THE RIGHT SUBPANEL SIZE

The main panel of your business will provide the power to your property. Subpanels have additional slots – anywhere from 4 slots to up to 12 slots. If you do not have any room in your main panel to install additional breakers or you need a control point near a certain area of your property, you should purchase subpanels. When trying to decide what subpanel size that you require, you must consider the following:

- 1. The amperage that you require of the subpanel

- 2. The additional demand placed on the main panel that stems directly from the subpanel

You must always ensure that your subpanel has the proper capacity to handle the amperage that you need it to handle. The size that you need will have a lot to do with the application that you are planning to use the subpanel. If you just need a subpanel for light tools or an area that requires the use of a television, you could use a panel that serves up to 60 amps. If you need much more, you could need one in the way of 60 amps to 100 amps. Always pay close attention to the amperage and consider the power that you will place on the main power box.

THE LOAD CALCULATION

When determining the subpanel size, you will be pleased to know that there is a calculation that you may use which is referred to as the “load calculation”. This specifies the total electrical load that may be safely run on a subpanel. You need to know the square footage of the area and the type of devices that will be run on the subpanel. By knowing these details, you will be able to figure out the right amperage and the right-sized feeder cable.

Electricians typically calculate using the load calculation. This calculation is part of the local electrical code. It includes the wattage of electrical usage, the equipment/devices that will be part of the subpanel, and then adds all of that together. That total is then divided by the number 240. The end result is the capacity – in terms of amperage – that the subpanel needs to be upon purchase and installation.

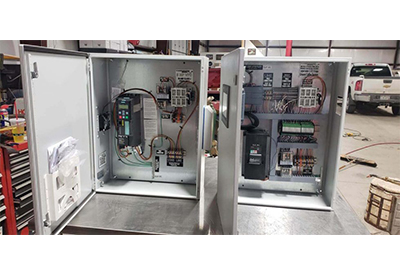

THE STRUCTURE AND WIRING

If you choose an indoor subpanel, the unit is not designed to be weathertight. It will only need to be mounted by the electrician of your choosing so that it meets the local and the national codes. Outdoor subpanels are designed to be weathertight, so all aspects are resistant to the weather. It is best to have a shelter in place around the subpanel so that moisture does not interfere with the functioning of the panel. By consulting with a professional electrician, you will be able to ensure that the structure and wiring is set according to the codes required in your area.

![]()

https://hardcore-electric.com/difference-between-main-panel-and-subpanel/