IMO Precision Controls: Foundations and Advances

April 27, 2021

By Owen Hurst

Earlier this month Panel Builder US had the opportunity to chat with IMO Automation to learn a little more about their operations in the US and how they are working to provide unique solutions and support to the panel building market in the US.

IMO was founded in 1972 in the UK and has been steadily expanding their global footprint ever since with 50% of their business now coming from the global market. IMO was originally founded on a strict set of principles that focused on quality and reliability, which were backed with unique warranty periods of up to 5 years.

Today those founding principles continue to be the key drivers of the company. Joe Covington, General Manager for North America at IMO discussed with us how the principles of the company have remained in focus and spoke of their supporting mantra, “we as a company have a philosophy of succeeding through the success of our customers, when our partners succeed IMO succeeds.”

After years of success in the UK and European markets IMO began expanding its business globally and entered into the US market with a direct base of customer support and operations located out of Atlanta, GA. Joe says, “The US market presented a host of opportunities for us as a manufacturer and it’s one where we knew we could be competitive which led to our emphasis and domestic investments”. IMO further recognized that their services are dependent on the customers’ needs and having an existing sales force and distribution network enhances the ability to service clients. The centre is the focal point of a hybrid sales model throughout the US that supports clients through direct representatives, manufacturer representatives, and regional distributors.

Further, the facility allowed IMO to institute direct support for clients with on-staff application engineers that can support clients in determining the proper solution for their needs. The ability to engage directly with IMO engineers provides additional advantages that have advanced IMO’s position in the US and provides unique opportunities for them to support industry growth.

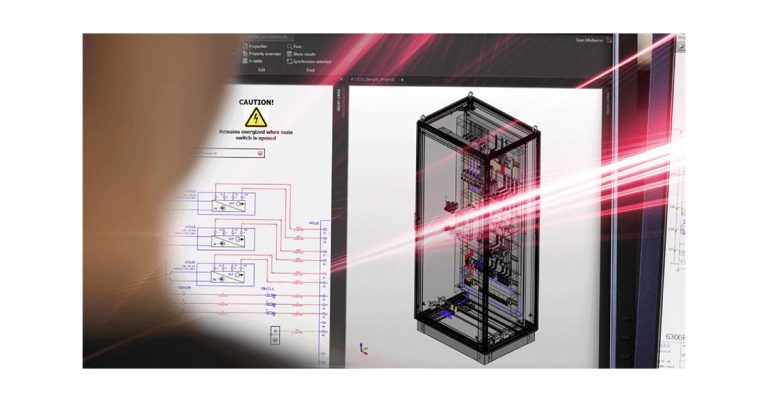

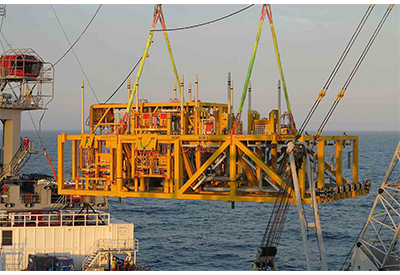

The advantages of engineering support are really a tribute to the breadth of UL certified products and solutions being delivered by IMO. Currently IMO services most Industrial Segments, with a predominance in HVAC, Food & Packaging, Automotive, Material Handling, Industrial Contracting, Light Assembly, Biopharma, and Wastewater. This strong background in industrial technology has also served IMO well in the development of solar safety products such as DC disconnects now trusted by many of the world’s leading inverter manufacturers supplying into the US market.

“At the moment, we are heavily focused on key industrial products such as UL MCB’s, DIN Terminal Blocks, Relays, Disconnects and Power Supplies which are driving growth” commented Joe. “We are very well positioned here to support new builds and legacy system upgrades wherever industrial controls are utilized.”

As IMO looks ahead the focus is to continue growing and supporting the OEM market in the US. The value developed through IMO’s direct to market strategy has been well received by customers and continues to be the driver of growth. This strategy supports OEMs and customer’s by allowing them to remain competitive in an environment where the competition is growing each day. The US market, while highly competitive, is one where IMO has been able to effectively differentiate itself and Joe notes that the focus and emphasis on the US as a key part of IMO’s global growth strategy will continue well into the future.

![]()