Discussing Building Controls with John Zappa

March 2, 2021

By Owen Hurst

In this special Monthly Market Company Feature we are discussing building controls with John Zappa, Owner and President of Building Controls Group a distributor for HVAC control supplies in St. Paul Minnesota. Buildings Controls Group has a UL508a fabricating facility that also specializes in the fabrication of UL508A industrial control panels for the HVAC and building automation industry.

John has an interesting history that has provided him with a deep understanding of the building controls market, its growth over the last 30 years and how trends are likely to affect the industry as we look ahead. John started his career studying heating and air conditioning, and refrigeration. After initially working in this field, he went back for additional training on the design and layout of HVAC equipment and systems.

This new course eventually led to working with a controls distributor for 25 years before making the decision to start his own company.

Building Controls Group was founded in 2013 by John and his wife Susan (Vice President) to provide supplies and support for building controls support and services to the rapidly growing market. John notes that in the early days they were able to secure a few key vendors like Johnson Controls, Tridium with their Vykon brand, and ACI Automation Components and Functional Devices. Now 8 years later, on they represent upwards of 85 different manufacturers.

We went on to ask John about some of the specifics of his business and some of the trends he has witnessed throughout his career.

Building Controls Group is an interesting name, can you tell us a little about the name and how you landed on it?

My wife and I wanted a name that was synonymous with our core competency, that being controls, HVAC, and building automation. Building Controls Group fit because it is generic enough that it speaks to all the solutions we provide from the boiler room to the board room and anywhere in between within a building. Examples would be Burner Boiler controls, air conditioning and room zoning controls, to card access, lighting, and security.

In what ways have you seen the growth of building automation and control expand?

Over the past 10-15 years it has been fascinating to witness the number of new controls manufacturers tapping into the market of building controls and automation. Some are brand new to the industry and are coming from varying backgrounds. For example, a company may have only had programming background and developed algorithms for saving energy and before they knew it found themselves as a manufacturer. Another example are existing manufacturers that had been focused specifically to HVAC but branched out to include the control side of the HVAC business.

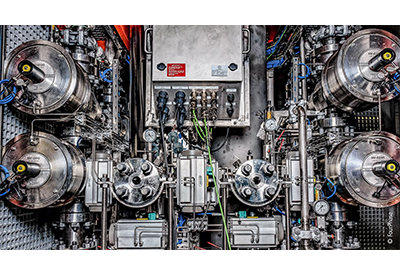

And it has not only been Control System manufacturers, but peripheral device manufacturers have also come out of the woodwork. These are manufacturers that complement the controls manufacturers with products like valves, actuators, sensors, and interface devices that connect to automation controllers and system.

To say the least the adoption of controls and growth of the market implementing them is a unique one that continues to grow.

What are some of the primary areas of buildings requiring advanced control solutions to operate? (What are the most common panels your team is building right now)?

There Is no one primary area requiring advanced control, what you are seeing is control and equipment manufacturers advancing with their own technologies. Many manufacturers of equipment, boilers, air handling unit, chillers, etc. have developed their own controls and now the distributors, contractors, engineering firms are acting as integrators to tie all these pieces of equipment or systems together on one platform, this also includes a buildings lighting, card access, security and fire monitoring.

Buildings you see now are being built with 2 or more types of IT infrastructure. Under the building’s operations, we call this Operational Network or OT. If it was a manufacturing facility, I can see adding a 3rd network solely focused on the equipment used for manufacturing.

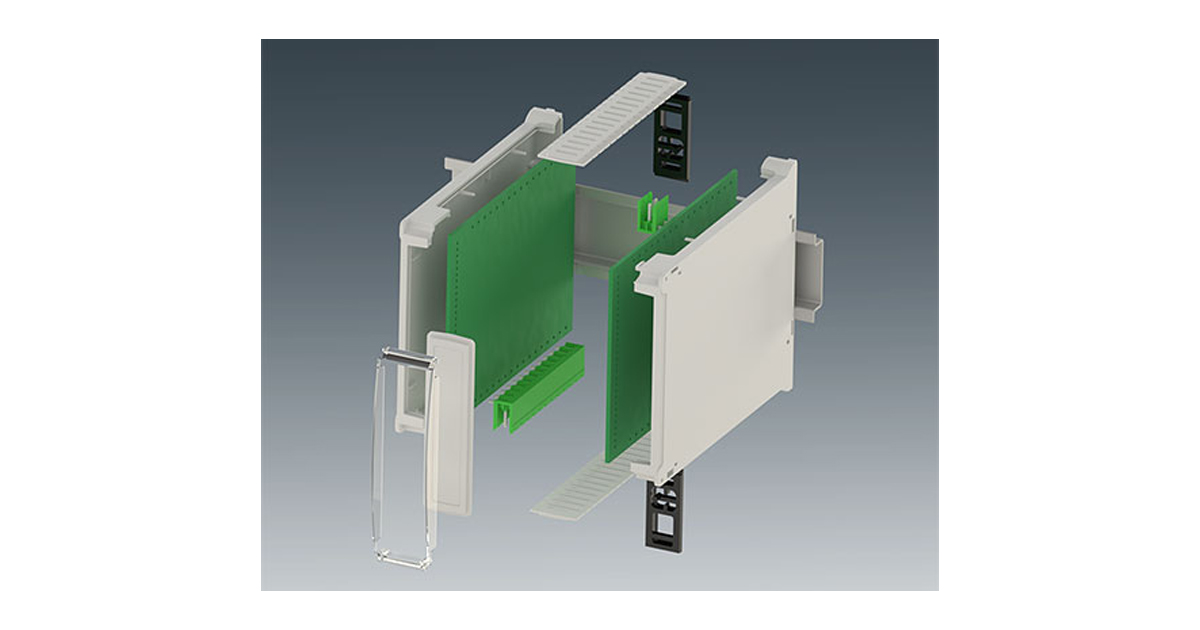

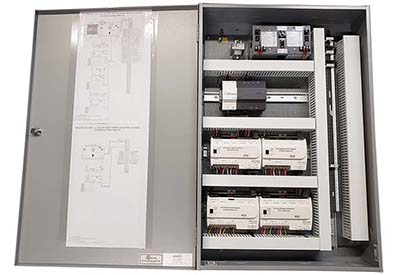

The most common panel our team builds are the (Prebuilt UL508 listed panel) These are empty shell panels that are customers can put their controllers in.

What difficulties are associated with building panels that meet the needs of the growing focus on building automation?

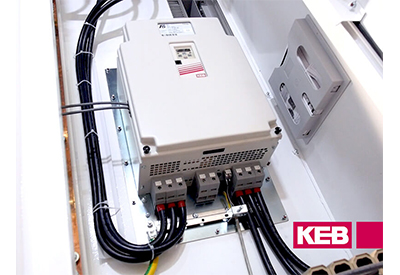

Not so much as difficulties as it is adapting with the changes happening in our industry. For example, 10 years ago, when building a simple control panel for running a boiler room you had a DDC or electronic controller with some relays, transformers, etc… Now that same panel would more than likely accommodate those items plus a router, switch, web based, or VPN device. Because it is expected that all your data and status of the system will be available on a phone or have remote monitoring, trending, or alarming built in.

As a UL508a fabricating facility, We have had some learning curves in applying these products appropriately according to the guidelines for UL508A standards. UL’s guidelines. Example is running cat 5 cable with 120v cable in the same wire race. UL has certain requirements when doing something like that.

Another focal point has been the increase in the use of wireless devices. When we have a Control Panel that needs to house a wireless controller, we need to look at the type of panel. (Steel vs Poly) or if any penetrations or holes need to be made for antennas.

So again, not difficulties but more an ability to offer flexible solutions that adapt with the current changes and trends in the industry.

Are you seeing any forms of standardization or build trends that emerging in certain sectors (ie. Commercial, institutional, industrial…)

Very simply put the biggest trend or consideration across the spectrum is security. With more remote access over the internet being expected, security has become the number one topic for control manufacturers, building owners and property managers.

In what ways do you develop prebuild panels/custom panels and what services do you offer after the panel has left your shop?

Building Controls Groups UL508 panel fabrication shop builds prebuilt panels of various sizes that can be purchased online or over the counter. The contractor can purchase this panel that is UL listed ready for their controllers to be placed and wired up. These are prebuilt in stock ready to ship.

We also offer fully custom panel fabrication, based on client submitted designs and schematics, or we can work with clients to develop designs and schematics for them. The custom UL508 panels that we design and build for are in many cases for retrofit applications where an old system is being upgraded.

Building Controls Group will work with the contractor to completely design the panel around the existing system, taking into consideration where the power comes into the existing panel, field wiring for sensors and actuators, and size of the available space.

Building automation is certainly an important focus for the controls industry, both for new builds and system upgrades. And as we look ahead companies like Building Controls Group will be critical to implement the necessary needs of that growing market.

![]()

Visit Building Controls Group – https://www.buildingcontrolsgroup.com/