Discussing Automotive industry Panel Design and More with MartinCSI

January 26, 2021

By Owen Hurst

Recently Panel Builder US had the opportunity to chat with Bill Sellitto, Vice President of Engineering and Jim Sellitto, Vice President of Business Development from MartinCSI.

MartinCSI (MCSI) is a Systems Integrator in Plain City, Ohio that provides Design & Integration of Industrial Control Systems to a wide variety of end-users including, Food & Beverage, Pharmaceuticals. Glass and Plastic, Chemical, Utilities, OEM, Packaging, and the Automotive sector.

MCSI was founded in 1991 by Joe Martin. Joe had previously worked for an integrator but recognized that there was another way of doing business and founded his company on the premise of designing efficient automation and control designs, with a business philosophy that equally supports clients and staff.

Currently MCSI has a staff of 25, with 16 fulltime electrical engineers that are primarily involved in electrical design, PLC programming, HMI development, as well as a growing focus on robotics and machine builds. The company also performs safety risk assessments and remediation and performs data collection.

This month our Market Focus Issue is looking at the automotive market and we discussed MCSI’s relationship with this sector and some of the trends they are witnessing as a designer of control panels and automation infrastructure for the automotive sector.

Bill and Jim note that the automotive market makes up roughly 50-60% of their current business if you factor in both direct automotive manufacturing and all the additional automotive component suppliers.

We asked Jim and Bill about what the process is when working with this sector and whether they have witnessed any disruption over the last when working with clients in this sector?

They noted that this really is a process and can start in several ways. But most notably is knowing what questions to ask the client and ensuring that the team has vetted the system or machine to ensure the design will meet the application needs.

With respect to knowing the right questions, Jim briefly summarized:

First question to ask – Whose standards are we going to use? Some clients have their own drawing standards that works with their existing system and components. Or MCSI also has its own standards that it has perfected.

The next big question to ask is which vendors are approved on their list? It is important to work with clients and spec in products they already have in stock or can easily acquire, notes Jim. “We want to make things easier for our clients and the panel shops.”

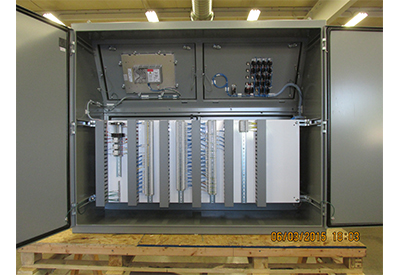

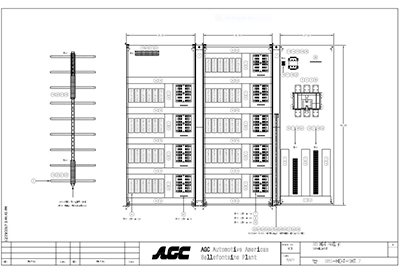

After that they get into some of the deeper considerations, like what is the incoming power feed and what is going in the enclosure? I.e., PLC’s, Ethernet switches, power supplies, transformers, power distribution etc.

Now to this point we have considered new panel builds, but a good portion of the work going into the automotive sector is focused on updating legacy systems. Jim discusses how most legacy system upgrades are focused on PLC upgrades, HMI’s, VFD’s and Servos. And the biggest trend now is upgrading to products that are current, but more importantly, are readily available.

After knowing the right questions, undertaking a proper site visit is necessary to fully vet and assess the application before the design process. Site visits are primarily done by account managers, most of whom are engineers themselves. They go in and vet the system, take any pictures that need to be taken, ask all the questions about how the line or machine operates, prepare any additional notes or specs required and then bring that info back to the engineering department.

And when on site MCSI also works with clients that are operating legacy systems in other areas to ensure equipment is operating as needed and meets code. As Jim and Bill note, the automation sector has been around for a long time and there is tremendous opportunity for upgrading systems.

At this point we asked Jim and Bill if they had seen any disruption on the ability to work within this sector and gain necessary site visits.

Both talked to the fact that there has not been as much disruption to the automation manufacturing market as they had expected. There of course was some disruption when you consider the ability to cold call on work opportunities, and that there was a reduction in capital improvements and upgrades. However, customers still need to maintain operations and will do necessary maintenance and upgrades.

Next, we discussed some of the most common trends and types of panels being used within the automotive manufacturing sector.

Jim and Bill both identified that the most common trend they are seeing among panels going into automotive manufacturing facilities is the ability to segregate low and high voltage. Jim discusses how automotive clients are asking that if, for example, they have a two-door enclosure, can they have something in between so the high and low voltage can be separated. They want to keep the 480V down to 120V on one side of the enclosure and have the ability to access to anything under 60 volts on the other side without shutting power off to do simple maintenance functions.

Naturally, this led to the real discussion of limiting the potential for arc-flash incidents. Bill notes that this is the biggest trend they are really seeing across the field. There is a growing demand for a disconnect with higher voltage that has it either segregated on one side with a different interlock system or in a separate side-by-side enclosure.

Regarding the most built or used panel they noted that there is really so much opportunity it is tough to narrow down. They see a lot of control networks being designed to replace mundane tasks and for implementing safety protocols. But for the most part the growth is accelerating in all areas of the market.

Finally, we asked about the process after their designs are out the door and have been realized in the application?

“Our participation does not end when designs go out the door,” notes Bill. MCSI works with clients, panel shops and local electrical contractors throughout the process and installation. When possible, an MCSI engineer is on-site for the install and start-up, as well as to ensure a smooth rollout and complete understanding of how to access and program the PLC Systems.

with clients, panel shops and local electrical contractors throughout the process and installation. When possible, an MCSI engineer is on-site for the install and start-up, as well as to ensure a smooth rollout and complete understanding of how to access and program the PLC Systems.

MCSI also provides the ability to connect with clients virtually to provide these services and develops virtual walkthroughs of the procedures that can be delivered to various shifts within a facility.

In all, MartinCSI delivers the experience and expertise in engineering design that Joe Martin prided himself on nearly 30 years ago. Their expertise in the automotive sector and beyond, and growing skillset in automation and control design sets them apart.

Jim Sellitto, Vice President of Business Development

Bill Sellitto, Vice President of Engineering

Visit MartinCSI HERE.