A Perfect System to Monitor Current

February 20, 2020

Power supply systems are the heart of machines and systems because they provide the energy required for operation. Overcurrent or short circuits can impact the power supply and cause machine downtime, production downtime and high costs. In order to maximize the reliability of the power supply systems, these problems have to be avoided. The Murrelektronik system consisting of high-quality power supplies and the Mico Pro power monitoring system, creates an optimum system with high machine availability.

Since its market launch in 2006, the innovative Mico current monitoring system has been used millions of times in machines and systems. In contrast to the miniature circuit breakers previously used, Mico triggers reliably even combined with long cables and the small cable cross-sections common in the 24 VDC range. This ensures long-term stable and error-free protection of load circuits in the 24 VDC range.

All channels in an installation are individually monitored for their current load with our patented tripping behavior. According to our early error detection principle, faulty channels are individually switched off. The source of the fault, such as overloads caused by worn loads or even short circuits, can be quickly and precisely localized using diagnostic functions. Once the error has been rectified, the affected channel is available again. Of course, channels are not switched off during intentional and short-term overloads, for example when starting capacitive loads. With the intelligent Mico control cabinet component, Murrelektronik is able to quickly and efficiently design troubleshooting solutions – the end of long downtimes and a factor for reliable production processes.

Solutions that fit the application perfectly

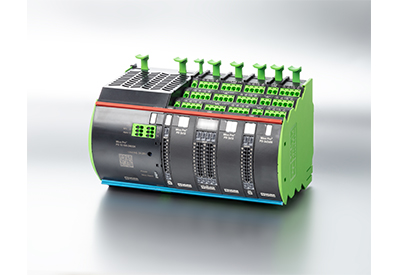

In order to meet the increasing requirements of automation technology in terms of modularity and miniaturization, Murrelektronik has further developed the Mico concept. With Mico Pro, Murrelektronik offers a modular solution: current protection systems can be designed that perfectly match the needs of users in their applications. The station has exactly the number of channels required for the specific application. The extensive portfolio offers versions with one, two or four channels, which are either preset or can be flexibly adjusted for the applications. Extensions can also be implemented in the future without any problems. An additional module can simply be plugged in if further channels have to be protected.

In order to ensure the reliability of the Mico Pro stations, Murrelektronik works with quality awareness in all process steps. We use of first-class components right from the development stage that are extremely efficient and are therefore not thermally stressed during operation. This results in a high MTBF value of over 2.4 million hours. Testing – for example with over 1,000 short-circuits – ensures the reliability of the components even in demanding situations. All this offers the dependability of a significantly long service life and regular availability.

Free up space in the control cabinet

The Mico Pro station can be designed with the exact number of slim modules required for the application, wasting no space in the control cabinet. As an additional option, power supplies specially developed for the Mico Pro system can also be integrated – they replace the power supply module and still offer the same diagnostics features: collective alarm message, 90 percent early warning, control signal for remote maintenance. The energy-efficient power supplies deliver up to 20 A in parallel mode and are connected intuitively and quickly using jumpers.

Another benefit Mico Pro offers that saves space are the potential distribution modules that connect several consumers with plus and minus (+24V and GND) to a monitored channel. This removes 0V distributions and the necessary terminal blocks from the control cabinet, freeing up a lot of space. The loads are directly wired to each channel and can be easily designated.

All this simplifies installations in the control cabinet and reduces the wiring effort. The result: lower overall costs.

Future-proof applications

If you have two or more control cabinets in a machine or system, you no longer need two power supplies when using Mico Pro. With the innovative high-current modules (> 10 A), the power supply can be transferred selectively from a main distribution cabinet to a sub-distribution cabinet. This selectivity guarantees that only the channel affected by the short circuit or overload is switched off.

Power-intensive consumers are increasingly being used in automation systems. Mico Pro provides reliable protection for these as well. M12 Power cables (L-coded) are the ideal interface to the IP67 products on the machine because they are designed for loads of up to 16 A and are defined as a standard by PI (PROFIBUS & PROFINET International).

Murrelektronik offers a convenient online configurator at www.micopro.murrelektronik.com to make it easy for electrical engineers to put modular systems together. With just a few mouse clicks, you can assemble the system exactly according to your requirements from the power supply module to the required Flex and Fix modules. You get both a visual 3D impression of his Mico Pro unit, and information like: the space requirement, the total current for the selection of the power supply – and a plausibility check that prevents planning errors in this early phase of the design.

Invest in a perfectly coordinated system

Mico Pro is an essential component of a future-proof power supply system. Murrelektronik offers a portfolio that provides a uniform system. It includes mains filters, power supplies, buffer modules and the Mico-Pro units, which round off the system as effective load circuit monitors.

![]()