Seven Steps to Industry 4.0

February 4, 2020

There’s a lot of buzz around Industry 4.0 right now, and for good reason. With the goal of creating “smarter” factories where all digital and physical assets are connected using artificial intelligence (AI), the Industrial Internet of Things (IIoT), cloud computing, robotics and other technologies, Industry 4.0 helps create more flexible, responsive and interconnected factories.

“More and more companies see Industry 4.0 as a competitive advantage,” says Michael Schneeweis, a Manager of Industrial Business at Graybar, “and are leveraging it to gain an edge in this ever-changing market through a more analytics-driven production approach.”

Getting there isn’t always easy or cheap, and managers of existing facilities can face particularly high hurdles in their quest to maximize the benefits of Industry 4.0. While the average U.S. factory was 16 years old in 1980, that number has since risen to 25, according to McKinsey. The average age of the equipment inside those plants has also increased from seven years old in 1980 to nine years old today. In most metals, machinery and equipment manufacturing applications, that number is even higher.

You’ve Come a Long Way Baby

Rewind the clock back 25 years — the average age of a factory today — and the Global Positioning System (GPS) had just become fully operational; NSFNET had just been decommissioned, thus removing the last restrictions on the use of the Internet to carry commercial traffic; and the average person still didn’t own a personal computer (let alone a mobile phone). Factories were running pretty much the way they’d always been, and acronyms like IoT and AI were still years away from going mainstream.

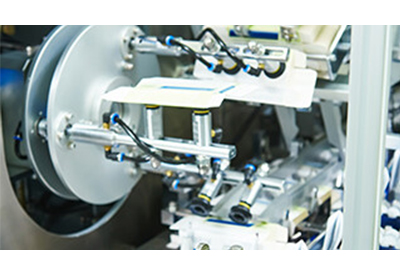

Factories have come a long way since then. Machinery is built with smart sensors that collect production data in real time; humans are working alongside robots to get tasks completed more quickly and additive manufacturing enabled by 3D printing has moved from the conceptual stage to full-blown reality. Combined, these and other advanced technologies represent a combination of systems that converge in a setting where all stakeholders have real-time insights into products, processes and people.

“This new wave … is driven by an explosion in the volume of available data, developments in analytics and machine learning, new forms of human–machine interaction (such as touch interfaces and augmented-reality systems), and the ability to transmit digital instructions to the physical world,” McKinsey points out. “Such complementary technologies can run smart, cost-efficient, and automated plants that produce large volumes — or, conversely, plants that turn out highly customized products.”

Seven Ways to Maximize Industry 4.0 Technology

Realizing the promise of Industry 4.0 isn’t always easy for managers of older factories and plants. Here are seven strategies that all managers can use to start reaping the benefits of IIoT, automation and other flagship Industry 4.0 technologies.

- 1. Listen to your customers. Having worked with numerous older plants that were asked by their customers to adopt Industry 4.0 technologies, Graybar Business Development Manager Kris Davis says this is usually the tipping point for factories. “When a company starts looking at how to add connectivity and data capture to a specific production line,” he says, “that imperative is usually being handed down by their customers.” In most cases, those customers want more visibility into the production process and supply chain activity, both of which can be enabled through improved data collection and sharing.

- 2. Conduct a thorough assessment of your current setup. If your facility is older and reliant on outdated infrastructure and equipment, do a thorough assessment of those assets to determine their age, capabilities and ability to connect with other devices. If, for example, your primary pieces of equipment operate in silos — meaning they’re not sharing data with one another — then that could be a good starting point for your Industry 4.0 upgrade. Ask yourself questions like: Do we have any smart devices on the plant floor? Is there a networking infrastructure in place that we can use with our new equipment? Is there a way for us to collect data? And if so, are we collecting that data and using it? “The answers to these questions will help you pinpoint your plant’s strengths and weaknesses on the Industry 4.0 spectrum,” says Schneeweis.

- 3. Assemble an Industry 4.0 project team. Adopting advanced technology that transforms the manufacturing floor isn’t a one-and-done project, nor is it something that can be approached on a one-off basis. According to Davis, the companies that get the best results are the ones that assign an overall project manager to the task and then assign other team members to head up the initiatives. “This isn’t a sales or IT initiative; this is something that should be approached from a true project management level,” he says. He also tells companies to select one systems integrator or high-end development company that can work directly with numerous technology partners to “put the whole system together.”

- 4. Put the spotlight on better data collection. Data is the new oil in the IIoT world, where it provides the foundation for good information sharing across the enterprise. As you assess your current setup, think about how you’re going to store the data, what type of data service you’ll put in place, how you’ll approach issues like cybersecurity and then how that data can be transformed into actionable intelligence. For example, if the machinery on the plant floor is delivering key performance indicators (KPIs) to a plant manager on an hourly basis, how will he or she use that intelligence to make good production decisions for the coming week? And, how will that data be delivered to the C-suite in a digestible, understandable format (e.g., reports, graphics, PowerPoint presentations, etc.) and then used to make better company-side decisions?

- 5. Assess your customers’ Industry 4.0 capabilities. If the companies you’re working with haven’t upgraded their own facilities to be able to receive, share and assess data across devices, then you may find yourself working in a vacuum. For example, a customer may want to know exactly how many parts your company is producing each day. Having this data will allow your customer to track specific parts in the supply chain and reply more accurately to its own customers (who want to know where their parts are). But if that customer can’t accept and utilize that information, then that data will be virtually useless. “This is something you want to look at early, particularly if you’re adopting IIoT, AI and other technology to fulfill a specific customer’s request,” says Davis. “If they’re lacking in technology themselves, don’t allow them to throw the whole responsibility of Industry 4.0 on you.”

- 6. Align your systems. For older plants that may have expanded their networks over the years by “dropping a new line over here on the side of the building” or “installing a patch panel to accommodate a new fiber line,” Schneeweis says now is the time to create a more cohesive approach that accommodates connected devices and technologies. For example, it’s common to see a standalone aisle of automated equipment that monitors its own activity, but that doesn’t push any of that information back to the manufacturing execution system (MES). “There are hundreds of plants that use this approach,” he says. “And while it’s not necessarily hurting their operations, those companies could definitely drive down the costs of production if they were actually doing something with all of that data.”

- 7. Put smarter devices on the plant floor. These include devices that store data and then deliver it back to a software system, server, programmable logic controller (PLC) and/or intelligent motor control. For most plants, this setup includes a way for a smart device to communicate with a server – typically a micro-data center where the information can be stored – plus Internet cables or fiber communications (for relaying the information to other sources). Even a plant’s lighting system can be connected to a smart device that utilizes Ethernet, fiber or wireless for connectivity. “You can even use plugs and receptacles to connect your smart devices,” says Schneeweis, “which, in turn, will send the data in question to another device or to a person who can then use it for good decision making.”

In return for implementing these strategies, Schneeweis says most plants will experience higher productivity levels, better supply chain visibility and improved efficiencies. “Data is the new arms race and more companies are going down this path,” he concludes. “To remain competitive in their respective markets, even older plants are going to have to start moving in this direction.”

![]()

https://www.graybar.com/store/en/gb/cm/company/news/seven-steps-to-industry-4-0