Top 10 Questions on Determining SCCR of Industrial Control Panels per the 3rd Edition of UL 508A

January 21, 2020

January 21, 2020

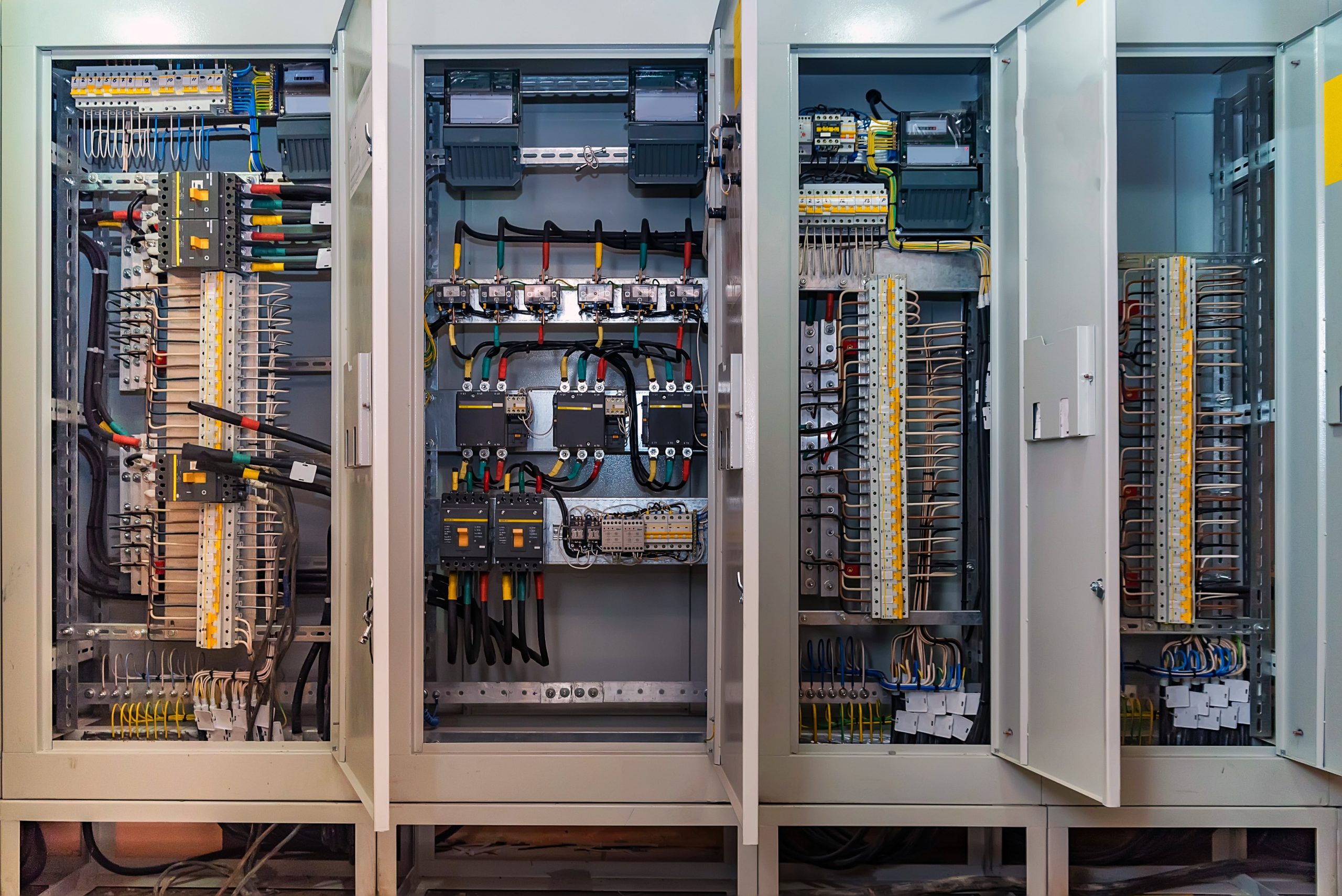

A short-circuit current rating (SCCR) for equipment is required by the National Electrical Code® (NEC®) 409.110(4) and 670.3(A), so understanding how the SCCR of an industrial control panel is determined and what the markings on the product signify will help ensure the safety of the industrial control panel.

To help increase industrial control panel safety, UL and Eaton’s Bussmann division experts have provided answers to the following frequently asked questions from the webinar, “Determining SCCR of industrial control panels per the 3rd edition of UL 508A.”

1. Why do passive components need to be in the branch circuit to have their SCCR increased by a current-limiting fuse or circuit breaker in the feeder circuit?

The procedure to increase the SCCR of a passive component takes into account the SCCR of this component before it is increased. This SCCR is dependent upon the use of a specific type of protective device protecting the passive component. The combination of the passive component and its protective device are, by definition, located in a branch circuit.

2. Why isn’t the peak let through applied to the branch circuit protection devices? What is the concept behind this?

The concept correlates with the requirements of NEC 240.86(A), which do not allow the use of fuse let-through (engineered method) to show protection of circuit breakers at fault currents higher than the circuit breaker marked interrupting rating unless the circuit breaker is passive (does not unlatch in the first half cycle). Molded case circuit breakers do not meet this provision so the use of fuse let-through is not permitted to show protection of circuit breakers at higher fault currents than their marked interrupting rating.

3. Why is it possible that the SCCR of a circuit breaker or fuse can be increased when connected to a secondary winding of a transformer while the SCCR of a circuit breaker or fuse in other applications cannot be less than the overall SCCR of the panel?

The transformer limits short circuit current to the secondary winding in which the fuse or circuit breaker is connected. If the fuse or circuit breaker has an interrupting rating at least equivalent to the available short circuit current, it will be able to successfully interrupt any level of short circuit current that the transformer can provide. In those cases, the fuse or circuit breaker is located in a circuit that has an SCCR that is determined by the interrupting rating of the fuse or circuit breaker located in the transformer primary. Fuses or circuit breakers providing feeder or branch circuit protection must be able to interrupt a minimum of the short circuit current available at the line terminals of the equipment being protected. As there is nothing to limit the available short circuit current to fuses or circuit breakers in these applications, their interrupting ratings cannot be less than the overall SCCR of the panel or equipment being protected.

4. What peak current values do I use if they are not shown in Table 4.2 for the current-limiting fuse I have selected?

In Table SB4.2, the dashes indicate that testing is not required for the fuse. This is typically the case for intermediate fuses (nonstandard case size) at short circuit currents of 50kA and 200kA. For instance, a 40A fuse is not required to be tested at 50kA or 200kA. The foot note to the table indicates: When values at 50 kA and 200 kA are needed, the standard case size shall be used. Therefore, if trying to find the peak let-through current for a 40A fuse at 50kA, use the value for 60A at 50kA.

5. Can the main fuse or circuit breaker be supplied in the field, and how is that accomplished to help ensure the SCCR marked on the panel is supported?

The main fuse or circuit breaker can be supplied in the field. Paragraphs 31.2.1, Exception No. 1 and 60.1 of UL 508A, the Standard for Industrial Control Panels, cover this. The SCCR marked on the panel is supported by applying the requirement in paragraph SB5.1.2 for branch circuit protection and SB5.1.3 for feeder circuit protection.

6. I have been told in some cases the interrupting rating of the main fuse or circuit breaker in a panel can be used as the overall SCCR for the panel. Is this correct?

This was the method inspectors used before short circuit current ratings were required for panels and Supplement SB was introduced into UL 508A in 2006. This method has flaws but seemed to be sufficient in most applications. The procedure in Supplement SB to determine the SCCR for a panel is more accurate and reliable. It takes into account the interrupting rating of the main fuse or circuit breaker, but takes it a step further to verify that the fuse or circuit breaker protects the equipment connected to the load side of these protective devices.

7. What SCCR are you seeing customers request? Is 5kA usually ok?

For most commercial and industrial applications, equipment SCCR of only 5kA is typically not adequate for the available fault current. Many industrials, such as in the automotive or food/beverage industry require 65kA or in some cases 100kA for their equipment. The available fault current may be lower than this at some points of installation, but this provides them the greatest flexibility.

8. When using a tested combination motor controller, a motor protector and contactor or variable frequency drive (VFD) for example, can different manufacturers be used or must it be exactly as tested?

Any manufacturer can be used if the equipment indicates “maximum ampere circuit breaker” or “maximum ampere class fuse.”. However, if a motor circuit protector (MCP – instantaneous only circuit breaker) or semiconductor (high speed) fuse is specified by manufacturer and part number, only this overcurrent device can be used. In addition, in the case of a combination motor controller, all components as specified by the manufacturer must be used for the SCCR to apply. For instance, if the combination motor controller includes the overload relay with the contactor, the SCCR may not apply for only the contactor without the overload relay.

9. Are series ratings allowed to be used in industrial control panels?

The use of current-limiting fuses or circuit breakers for tested series ratings are not permitted to be used in industrial control panels. Hence the use of current limiting overcurrent device let-through for tested combinations of circuit breakers with upstream circuit breaker or fuses is not permitted to raise the assembly SCCR above the interrupting rating of the circuit breaker.

10. Who is responsible for the SCCR calculation date; the original equipment manufacturer (OEM) or installer?

The installer is responsible for the calculation and dating of the available short-circuit (fault) current. During the design stage, the design engineer should estimate the available fault current and communicate the required SCCR to the OEM. However, this is an estimated value that must be confirmed based on the actual installation by the installer.

Register for the on-demand webinar and learn more about the process for determining the SCCR needed for a given industrial control panel using UL 508A Supplement SB.

![]()