Determining SCCR for Industrial Control Panels and Industrial Machinery

December 30, 2019

Article co-authored by UL and Eaton’s Bussmann division experts.

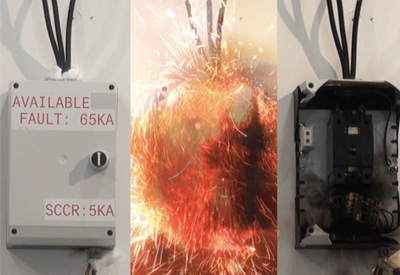

A short-circuit current rating (SCCR) for equipment is required by NEC® 409.110(4) and 670.3(A). SCCR represents the maximum amount of current that the assembly can safely withstand under short-circuit conditions. Additionally, the following general statement related to SCCR is included in NEC 110.10:

“The overcurrent protective devices, the total impedance, the equipment short-circuit current ratings, and other characteristics of the circuit to be protected shall be selected and coordinated to permit the circuit protective devices used to clear a fault to do so without extensive damage to the electrical equipment of the circuit.”

Understanding how the SCCR of an industrial control panel is determined and what the markings on the product signify will help ensure that the industrial control panel is adequate for the available fault current at the point of installation.

Industrial control panels are defined by the NEC section 409.2 as an assembly of two or more power circuit components, control circuit components, or any combination of power and control circuit components. Industrial control panels are listed in accordance with ANSI/UL 508A, the Standard for Industrial Control Panels, and covered by UL product category NITW (Industrial Control Panels) as factory-wired assemblies of industrial control equipment, such as motor controllers, switches, relays, and auxiliary devices. The panels may include disconnecting means, power distribution blocks, motor controllers, and branch-circuit protective devices. UL Listed products installed and used in accordance with their listing are considered by the NEC to meet these requirements. Short-circuit current ratings marked on the equipment provide the information needed to help ensure a safe, code-compliant installation.

For UL 508A panel manufacturers, two options are available to obtain the needed SCCR for a given panel:

- Apply the method described in UL 508A, Supplement SB (determining SCCR based on the components in the power circuit). If the industrial control panel contains only control circuit components, marking the SCCR is not required (also noted in NEC section 409.110(4) Exception).

- Test a panel to achieve ratings higher than the value determined using Supplement SB.

UL 508A Supplement SB is the preferred option for nearly all industrial control panels. The overall process of this is to:

- Identify the lowest component SCCR and/or component combination SCCR rating with an overcurrent protective device (OCPD).

- Increase the branch component SCCR and/or component combination SCCR rating with a feeder current-limiting OCPD.

- Identify the lowest interrupting rating of overcurrent protective devices in the industrial control panel.

The lowest component SCCR (steps 1 and 2) and the lowest interrupting rating of the overcurrent protective device (step 3) results in the overall assembly SCCR.

For step 1, power circuit components (components that supply power to external loads such as motors, lighting, heating, appliances, or convenience receptacles), the SCCR is determined by either the product markings or the instruction sheets. If there are no product markings, a default value can be used as indicated in UL 508A, Supplement SB, Table SB4.1.

As mentioned previously, the SCCR of the industrial control panel must be adequate for the available fault current at the point of installation. In most applications, a default SCCR of 5 kA is not adequate.

For these installations, UL 508A Supplement SB allows the manufacturer of the industrial control panel to achieve the required SCCR by using power circuit components that have been tested by the component manufacturer for a high fault rating and incorporating them into the industrial control panel manufacturer’s UL report (Procedure).

For step 2, it’s possible to raise the ratings of branch power circuit components – those on the loadside of the branch-circuit overcurrent device (the overcurrent device closest to the load). Any component or overcurrent device on the lineside of the branch-circuit overcurrent device is in the feeder circuit. When a current-limiting device (fuse or circuit breaker marked current-limiting or a transformer) is located in the feeder circuit, it can be investigated to determine if it can increase branch circuit component SCCR ratings. When transformers are used, both the branch-circuit overcurrent device interrupting rating and the component SCCR are able to be increased.

However, when current-limiting overcurrent devices are used, only the component SCCR can be increased. It is not permitted to increase the branch-circuit overcurrent device interrupting rating.

The final step is verifying the lowest interrupting rating of the overcurrent devices in the industrial control panel. If this is lower than any power circuit component after the steps above, the assembly SCCR is lowered to this value.

Although the overall process may seem simple and straightforward, understanding the rules of UL 508A Supplement SB and the proper application of devices is a complex and challenging concept. This is especially true with regards to the use of current-limiting devices as noted in step 2.