Three strategies for designing better control panels

July 31, 2019

Control panels present a major opportunity for manufacturers to improve operational efficiency, boost flexibility, reduce engineering costs and save valuable floor space. With this in mind, Omron has developed a unique set of guidelines, known as “Value Design for Panels,” that can help manufacturers create better control panels.

Let’s take a look at a few key strategies.

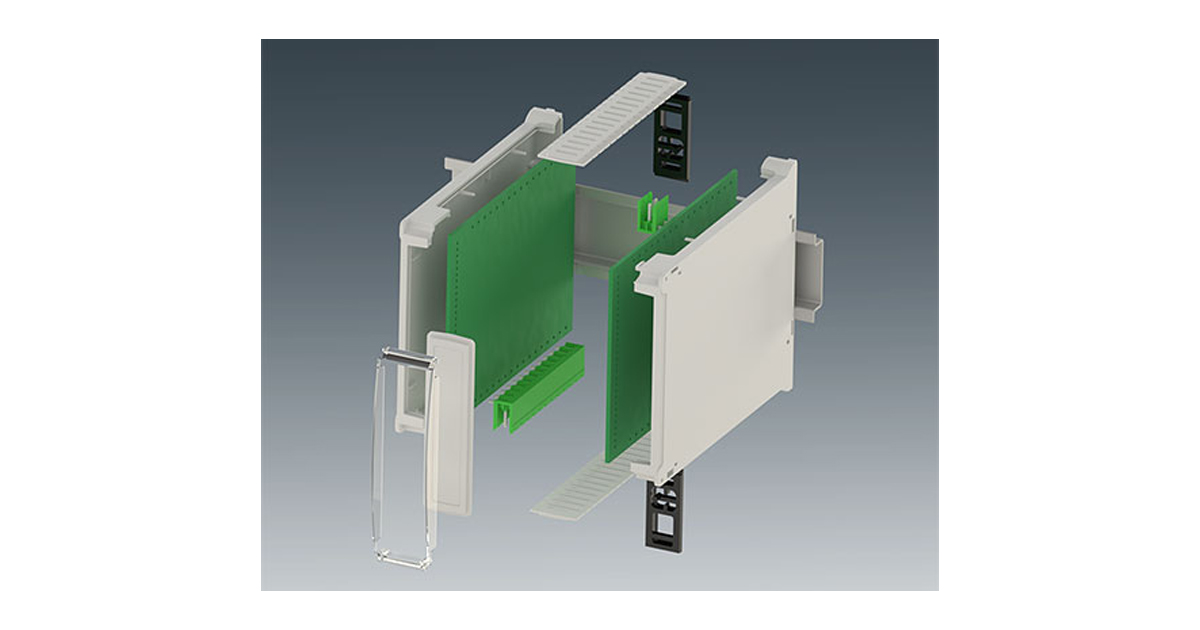

1. Embrace a slimmer design.

In manufacturing, it’s always helpful to find ways to free up space. Even if there are no pressing needs for new equipment at a given time, there probably will be in the near future. Lighter-weight control panels with a narrower structure can help create surplus space for future expansion and the addition of more components.

In addition to enabling manufacturers to use space more flexibly, a lighter-weight control panel design also reduces costs of transportation. It’s difficult to predict future needs for the rearrangement and addition of control panels, but should such a need arise, a slimmer design will make the transition process much easier.

2. Optimize Heat Dissipation.

Improper heat dissipation can have a very negative impact on the lifespan of a control panel. When panels malfunction, the downtime caused by maintenance and/or replacement can significantly lower productivity. For this reason, it’s essential to optimize the air circulation within control panels and reduce hot spots.

One easy way to improve air circulation and heat dissipation is to make sure the heights of all the panels are uniform. Varying heights create dead space, and the dead space in turn produces hot spots. In addition, when panels are designed to consume less power and generate less heat overall, they can more effectively be mounted side by side at an ambient temperature of 55°C to further improve air circulation.

3. Make Wiring Both Simple and Secure.

Omron’s Innovative Push-In Plus technology provides a robust grip that keeps wires firmly in place. What’s even more stunning about this technology is that the high pull-out force goes hand-in-hand with an exceptionally low insertion force. In fact, it takes less effort to insert a wire into a Push-In Plus terminal block than it does to plug in a typical set of earphones!

The secret to making wiring both easy and robust is Omron’s innovative spring mechanism. Thanks to this technology, it’s even possible to insert wires with ferrules and solid or stranded wires into a Push-In Plus terminal block.