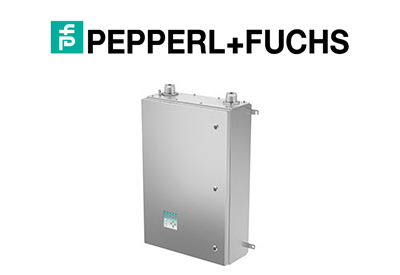

Pepperl+Fuchs: New Purge Solution for Large Enclosures: Bebco EPS 6100 Series

December 1, 2019

Pepperl+Fuchs introduced the latest addition to its market-leading portfolio of purge and pressurization solutions at this year’s SPS fair in Nuremberg.

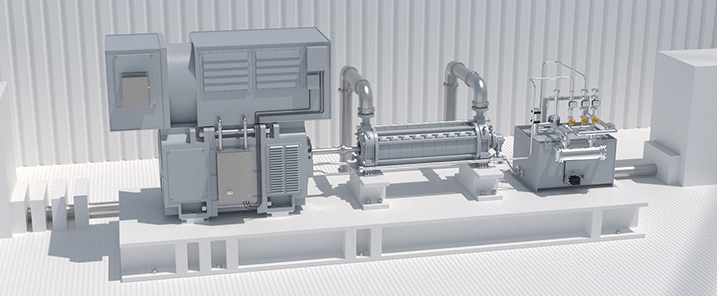

The Bebco EPS® 6100 series was specially designed for use with large motors, drives, compressors, and enclosures in ATEX/IECEx Zone 1 hazardous locations. The largest purge and pressurization system available from Pepperl+Fuchs to this day, the automatic 6100 series system can purge enclosures that are larger than 12.2 m³ (450 ft³). This new system is ideally suited for applications in the chemical, petrochemical, and oil and gas industries.

Versatility for Demanding Applications

The 6100 system consists of a control unit, enclosure protection vent, low pressure sensor, and optional temperature sensors. The configurable control unit features temperature and pressure compensation, an extra output for control or alarm, two selectable intrinsically safe inputs for various actions, and up to three temperature sensor inputs that can monitor various points within a motor housing. The intrinsically safe user-interface can also be mounted in a separate enclosure near operating personnel for quick access and easy system monitoring.

To meet any application requirement in large enclosures, enclosure protection vents are available with five flow rates to choose from (up to 14,000 l/min). The intrinsically safe low pressure sensor provides an accurate enclosure pressure reading for safe operation in hazardous locations. The pressure sensor, which can measure internal pressure from 0 to 25 mbar, can be remotely located at the motor’s low pressure section for correct, safe motor pressure readings..

Bebco EPS®—The Leaders in Purging Technology

For more than 20 years, Bebco EPS® purge and pressurization systems have provided well-proven design and reliable protection to the process automation industry. As the most recognized brand, Pepperl+Fuchs is the global leader in the purge and pressurization market, continually offering users a safe and economical approach to installing electrical equipment in hazardous locations. With offices in more than 140 countries across the globe, our experts are always nearby and ready to support anywhere in the world.

Highlights of 6100 Series Purge and Pressurization System

- Certified for ATEX and IECEx Zone 1

- Automatic system with menu-driven programming

- Maximum flow rate of 14,000 l/min

- Intrinsically safe user-interface for system programming and monitoring

- Control unit monitors system operation and controls enclosure power

- Auxiliary contact outputs for alarm or control

- Multiple temperature inputs for monitoring and control

- Automatic pressure compensation for excess leakage from motor

Please note: datasheet for the 6100 series will be available on this site soon!