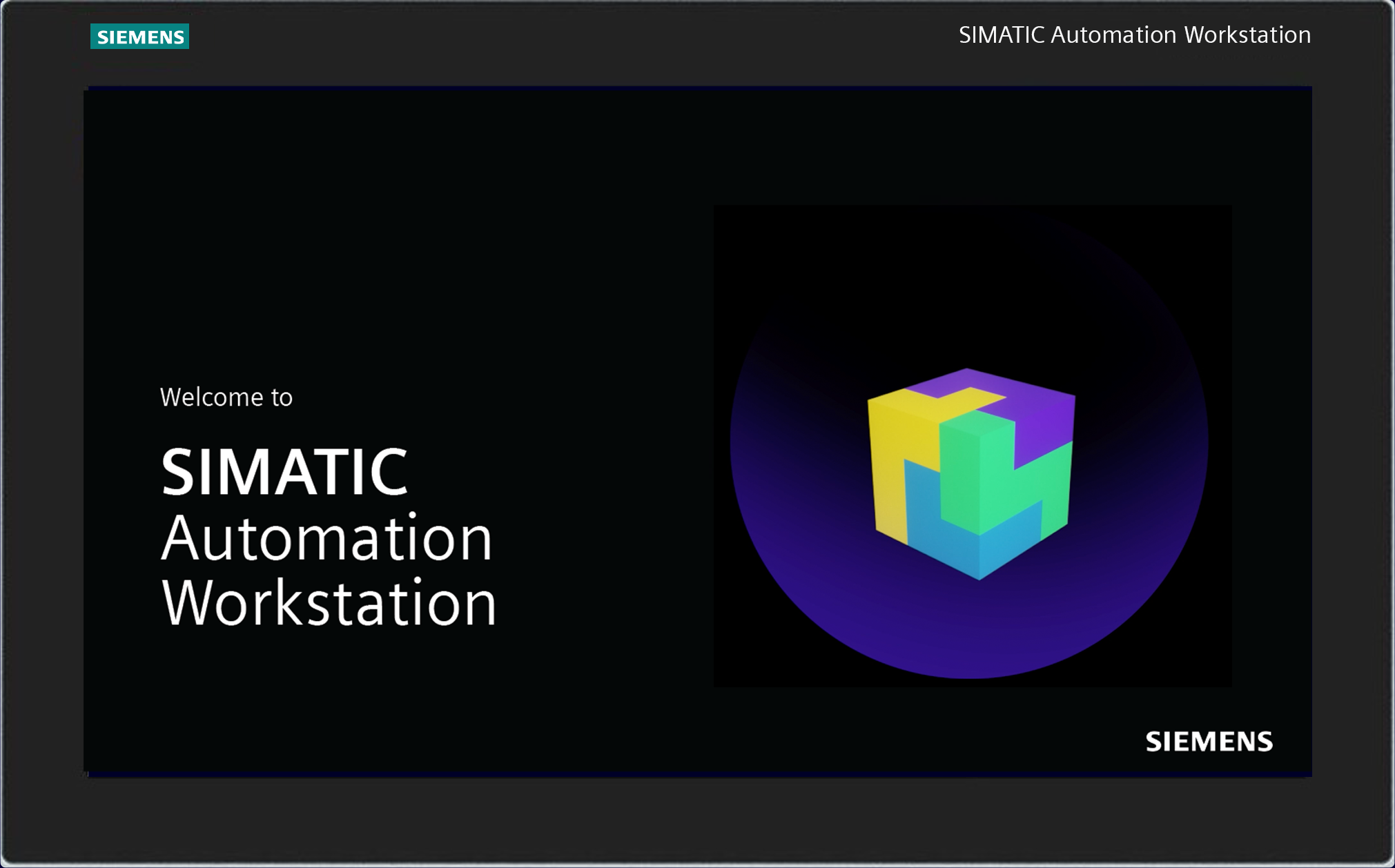

Siemens Launches New SIMATIC Workstation, a Breakthrough in Automation Technology

Siemens has announced a breakthrough in the longstanding challenge of closely managing numerous hardware control points throughout the factory. The “SIMATIC Automation Workstation,” allows manufacturers to replace a hardware PLC, a conventional HMI and an edge device with a single, software-based workstation. This ushers in Internet Technology (IT) workflows to Operational Technology (OT) environments.

PLCs are often referred to as the brains behind factories, energy grids, office buildings, and trains. Hundreds, even thousands, of these boxes can be found throughout plants, each one requiring extensive programming to keep it current, secure and aligned with the other PLCs in the environment. On the contrary, every Siemens SIMATIC Workstation can be viewed and managed from a central point. Since programming, updates and patches can be deployed to the entire fleet in parallel, the shop floor remains in synch. One example of the value this brings occurs when a facility needs to ramp up or down quickly in response to fluctuating demand. The manufacturer is no longer tied to boxes on the floor and can quickly deploy programming adapted to the current demand scenario.

The Siemens SIMATIC Workstation is an on-premises OT device that utilizes Siemens industrial edge technology to allow for high data throughput with the low latency needed to allow manufacturers to run an expanded variety of modular applications. This applies not only to traditional automation tasks like motion control, sequencing, and safety, but it becomes the platform for future, novel automation tasks that incorporate industrial AI-in-the-control-loop, such as visual inspection and robotic grasping and placing.

“In times of volatility in demand and supply, manufacturers can no longer be tied to boxes on the floor that need to be individually — and manually — updated. Centralized management is the best option for increasing visibility and security for manufacturers managing a high number of automation control points,” said Del Costy, President and Managing Director of Siemens Digital Industries. “This makes automation highly scalable and changes the game for how factories can be managed. We have arrived at a moment where we are only limited by our imaginations.”

The initial deployment of SIMATIC Workstations will be deployed across a number of Ford Motor Company’s manufacturing facilities.

Following the launch of Siemens Xcelerator in 2022, Siemens has released many new innovative solutions to the market. The SIMATIC Workstation is the newest addition to the platform and will be adapted to serve other industries and customers.