No Need to Sacrifice Speed for Safety – Validate Human-Robot Applications With the Collision Measurement Set PRMS

November 2, 2020

Robots have been a core element in businesses for a long time now. They are used to support humans undertaking strenuous or monotonous tasks in factories. It’s precisely this support that often leads to close cooperation between human and robot.

To establish and maintain safety for human and robot, the EU research project Rossini is working to disseminate and optimise human-robot collaborations (HRC). Fraunhofer IFF is working on a method for collaborative robots to assess the hazard potential of transient impact. Owing to the principles involved, the measurement of collision forces requires a fixed measurement device, which is why transient impact cannot be simulated. The transient impact can be assessed by converting the collision forces measured at the fixed measurement device, as proposed by Fraunhofer IFF. This method avoids a low robot speed, while the high safety level is unchanged.

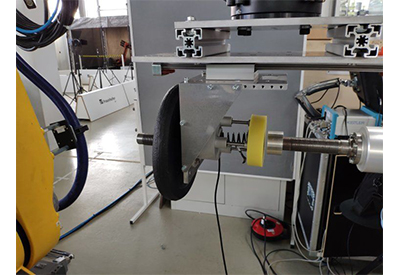

The measurement device that’s used is the collision measurement set PRMS (Pilz Robot Measurement System) from Pilz. This PRMS Set is used to validate human-robot applications by determining the force and pressure arising from a potential collision. The new procedure developed by Fraunhofer IFF was validated with various robots using the Pilz PRMS. As such the new procedure establishes a high level of safety for humans, taking transient impact into account, despite increased robot speed.

![]()

https://www.pilz.com/en-US/company/news/articles/225730