Yokogawa to Release Collaborative Information Server

October 20, 2020

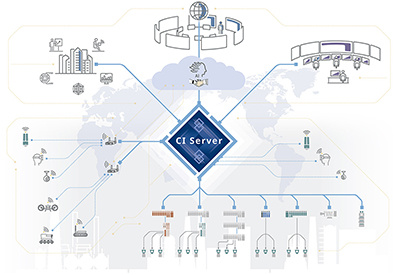

Yokogawa Electric Corporation has recently developed the Collaborative Information Server (CI Server) and will be releasing it to the market in January 2021 as part of the OpreX Control and Safety System family. The solution will integrate the handling of all kinds of data from plant facilities and systems to enable the optimized management of production activities across an entire enterprise, and provide the environment needed to remotely monitor and control operations from any location. By reducing the need for travel, this also helps to lessen the risk of infection with COVID-19.

Development Background

As supply chains stretch across the globe and customer needs grow ever more diverse, many companies today are having to deal with increasing complexity in the supply of raw materials and in their operations. At the same time, they are experiencing labor shortages as their most experienced operators age and retire. Under these circumstances, companies must pursue efficiency in their operations and make decisions quickly in response to market changes if they are to remain profitable. And to streamline operations and ensure the safety of their workforce, there is a rapidly growing need for remote solutions that will enable personnel to work together without actually having to be on site.

To meet these needs, Yokogawa has developed CI Server, a solution that automatically aggregates the data that has been acquired from plant facilities and systems so that personnel in any location can monitor and operate them and have access to all the information needed to make swift and effective decisions.

Features

- 1. The streamlining of operations and assurance of safety through an operating environment that can be accessed anywhere

A plant operates most effectively when there is full collaboration between plant operators, experts in areas such as maintenance and quality management, and decision makers at headquarters, as well as with other plants. CI Server provides a remote operation environment that supports wide-area communications and allows plant operations to be monitored and controlled from remote locations such as integrated operations centers. CI Server can be used from any PC or mobile device with a web browser to monitor and control a plant’s operations. Efficient operation from any location is facilitated by creating a suitable dashboard for an organization and granting the necessary access permissions.As well as helping to facilitate smooth collaboration among decision makers and other experts who are not at plant sites, CI Server also aids in the efficient operation and management of power plants that are often spread out over a wide area and situated in harsh environments, offshore installations, and other facilities. Furthermore, by eliminating the need for travel to plant sites, CI Server reduces the need for interpersonal contact and thereby leads to a lower risk of COVID-19 transmission for individuals, companies, and the community.

- 2. Smooth data integration and centralized management of the information needed for swift decision making

Facilities and systems often differ in the data formats and the communications protocols that they employ, and this complicates the aggregation of information and the management of data in a unified format. CI Server supports a range of communications protocols, and can not only acquire process data from control systems, but also aggregate data such as the operational status of facilities and equipment, raw material and finished product inventory, and energy consumption. Data on equipment maintenance, product quality, and other items are all gathered automatically in real time, converted to a unified format, and linked and associated. Data from a wide variety of systems and devices made by different vendors can also be gathered and integrated, both on an individual and multiple plant basis.The collection and organization of the required data using a unified format previously had to be done manually. The automation of these tasks by CI Server saves time and ensures that the right information is delivered in real time to the right persons, for swift and effective decision making. CI Server enables a quick response to market changes and aids in the optimization of costs and enhancement of operational efficiency not only at individual plants but across an entire company’s manufacturing operations.

- 3. Use of data in operational improvement activities and in applications

Not only is CI Server’s integration of data useful in managing plants, it also helps to improve production efficiency and quality. CI Server enables the linkage of data in a unified format so that it can be used across the board in information systems, quality improvement systems, data analysis applications, and other such systems, and the data collected over long time periods can be automatically incorporated into and utilized by such systems and applications.For example, in process industries where the quality of raw materials and the soundness of production equipment is closely linked to the quality of finished products, the analysis of data with the assistance of artificial intelligence (AI) software can identify new correlations and important key performance indicators that can help to reduce failures and improve overall operations. Furthermore, by constructing a digital twin* for a plant using data that has been integrated by CI Server, it is possible to verify new solutions, new parameter settings, and other such operational improvements in advance.

* A model that replicates physical assets and processes in the real world by using real-time data and other sources. It enables simulation, diagnostics, and prediction.

Shigeyoshi Uehara, a Yokogawa vice president and head of the IA Systems and Service Business Headquarters, says, “The new Collaborative Information Server solution provides the requisite data management infrastructure for customers to carry out their digital transformation (DX). Yokogawa calls the future of the manufacturing industry IA2IA, industrial automation to industrial autonomy, and we will help industries with this migration from being automated to being autonomous. Yokogawa possesses solutions to improve operational efficiency, energy efficiency, quality, and other aspects through data utilization, and with CI Server will provide support to customers for improved production activities and for sustainable business growth.”

Major Target Markets

Oil and gas upstream, midstream gas and liquid pipelines, petrochemicals, chemicals, renewable energy, power, pulp and paper, pharmaceuticals, food, mining, iron and steel, and water distribution and wastewater treatment

Applications

Plant monitoring, operation, control, data collection, data storage, etc.

![]()

https://www.yokogawa.com/news/press-releases/2020/2020-10-19/