Schneider Electric’s Intelligent Enclosures Streamline Process Automation and Safety System Engineering

November 11, 2019

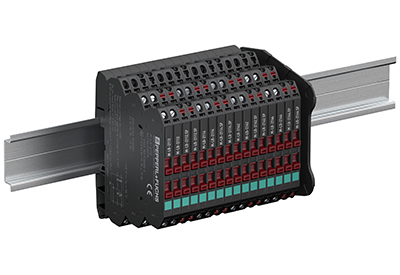

Schneider Electric has revealed the newest generation of its intelligent enclosures for EcoStruxure™ Triconex® safety and EcoStruxure Foxboro® distributed control systems.

Designed for oil and gas, petrochemical, chemical and other high-hazard industrial enterprises, the new enclosures speed project execution and decrease start-up costs. The pre-engineered, pre-tested enclosures support Schneider Electric’s flexible, intelligent engineering program, which shortens project schedules and increases project execution flexibility. The intelligent enclosure line includes:

- EcoStruxure Triconex safety field mounted intelligent enclosure, designed for use outdoors (including hazardous areas) to provide the flexibility to distribute I/O where and when required.

- EcoStruxure Foxboro DCS equipment room intelligent enclosure, designed to be installed in air-conditioned non-hazardous equipment room environments.

- EcoStruxure Foxboro DCS field mounted intelligent enclosure, designed for use outdoors (including hazardous areas) to provide the flexibility to distribute I/O where and when required.

“Intelligent enclosures perfectly exemplify our commitment to drive investments in our core process automation technologies, with the aim of helping our customers increase operational profitability,” said Hany Fouda, vice president for process automation systems portfolio. “Traditional project designs usually undergo several iterations, which means wasted time waiting to lock the configuration into a specific I/O module. The team can then build and ship the system faster. Field wiring and control room construction can start much earlier. A faster startup means faster time to production and therefore faster time to revenue.”

The intelligent enclosures significantly reduce cabinet design time and simplify system design; require fewer drawings and documentation; and involve less engineering, review and approval cycles. Locating universal I/O in the field radically reduces the number of wiring connections and traditional marshalling cabinets needed, which in turn reduces termination manpower and costs. As a result, intelligent enclosure customers have experienced:

- 25 percent reduction in cabinet engineering design and documentation time

- 30 percent reduction in project schedules

- 30-50 percent reduction in traditional marshalling cabinets

Intelligent System Design for Faster, Easier Commissioning

An intelligent system design across the plant starts with the intelligent enclosures. Schneider Electric’s flexible, intelligent engineering program decouples hardware from software, removing the need for full staging and Factory Acceptance Tests (FAT). Schedule risks are lowered because process data can be used earlier. Industrial engineers can leverage best practice rules, templates and virtual engineering and testing for decreased design errors and increased operational readiness. The intelligent design then extends to commissioning. Because the intelligent enclosures and programming are consistent and managed and tested in the factory, commissioning cycle time is shortened. With the pre-designed intelligent enclosures, much of the pre-FAT requirements are either eliminated or shortened.

Designed for High-Hazard Industries

Schneider Electric’s new line of intelligent enclosures is ideal for high-hazard industries and can be connected to a wide range of field devices. Each is a pre-certified cabinet fully packaged with:

- Universal I/O modules with adaptive field termination panels

- Choice of redundant power supply voltages

- Comprehensive cabinet documentation

- Standard installation and commission guides