Germ-free Holographic Touch Interaction

June 21, 2021

By Glenn ImObersteg, CEO, Holo Industries LLC

Americans took approximately 3.6 billion days off from work annually due to health-related illnesses, accounting for $127 billion in lost economic input. That was before the pandemic.

As social distancing, and masks, became the “New Normal” companies scrambled to find ways to protect their employees and customers from contacting Covid-19 and other contaminants. QR codes on cell phones, microbial touch screens, buttons that squirt antiseptic, and other remedies quickly entered the market, but most were impractical or problematic. Using QR Codes on smartphones to launch a payment app or access a menu for instance, could divulge the user’s location, insert a virus, or add a malicious Wi-Fi network, antiseptic needs to be replenished, and microbial screens have a short shelf-life.

Holographic touch is a practical, germ-free way for employees and customers to interact with touchscreens, control panels, and other HMI devices so businesses can thrive during and after the pandemic. Using this this ground-breaking new technology everyone can now safely touch an image, press buttons, scroll through a menu, spin an object—even sign their name—in mid-air. (Photo 1)

Principals of Holographic Touch

Holography is a technique that enables a light field to be recorded and later reconstructed when the original light field is no longer present, due to the absence of the original objects. Since Dennis Gabor developed the theory of holography while working to improve the resolution of an electron microscope in 1947, Holographics has occupied a special place in the realm of fantasy, illusion, magic, and theatrical special effects. The technology had no practical applications outside the field of entertainment.

Modern holograms utilize lasers as the light source, creating vibrant images. Traditionally, a hologram is made by shining one beam of light directly into the recording medium, and a second beam onto an object in such a way that some of the scattered light falls onto the recording medium. This beam splitting technique can create very intricate and realistic virtual images.

With an emphasis on safety & health protocols post Covid-19, today’s holographic applications span far beyond the entertainment business. Hologram and sensor technology are enabling contactless touch that aims to revolutionize human machine interfaces (HMI).

Case Study

Holo Industries, in collaboration with Asukanet and other suppliers in the sensor and optics fields, have developed a unique combination of holographics, software and infrared sensors that generate a contactless, mid-air technogy called Holographic Touch(TM)

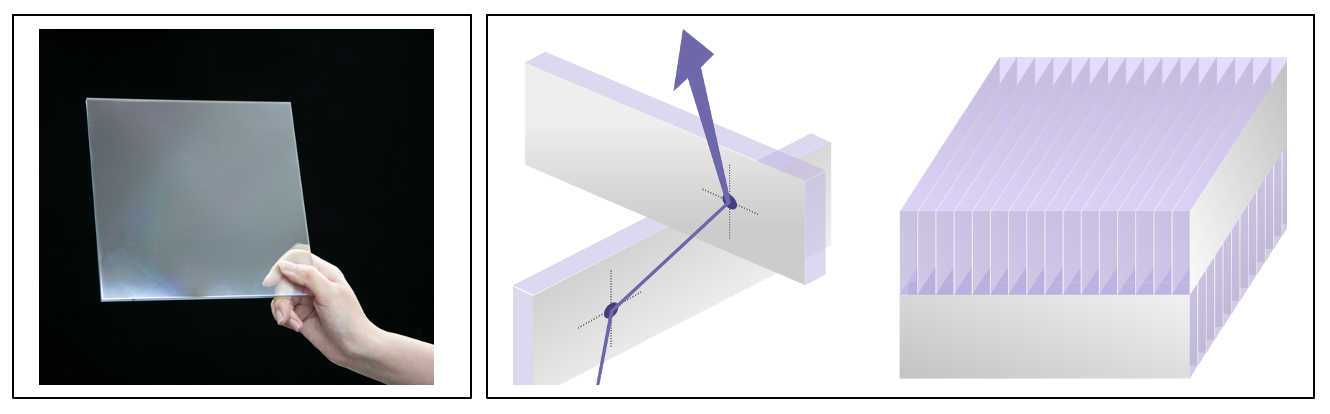

The Holographic Touch monitors projected images through light guides to an ASKA3D holographic plate (image 2) consisting of methodically positioned vertical mirrors measured in hundreds of microns. This technology creates Holo Industries’ holographic 1:1 images in mid-air.

To create a precise and reactive Holographic Touch platform, we add:

- Proprietary optical hardware for accuracy and clarity

- IR Sensors consisting of light emitters and detectors, an optical light guide with lenses and a controller IC that is connected to a host.

- Windows or Linux Operating Systems & Holo Industries’ Source Code

- APIs for customer-specific applications

The resulting Holographic Touch image is clear, crisp and very responsive (50 millisecond reaction time), even when wearing gloves.

Holographic Touch Configurations

Holo Industries manufactures two models, in sizes ranging from 100mm (4”) to 640mm (24”):

Stand-alone, containing a single board computer, programmed by Holo to customer specifications.

Tandem, sold without an SBC, because they are designed to interface via HDMI and USB to another terminal or CPU, (like a high-end coffee machine, for instance).

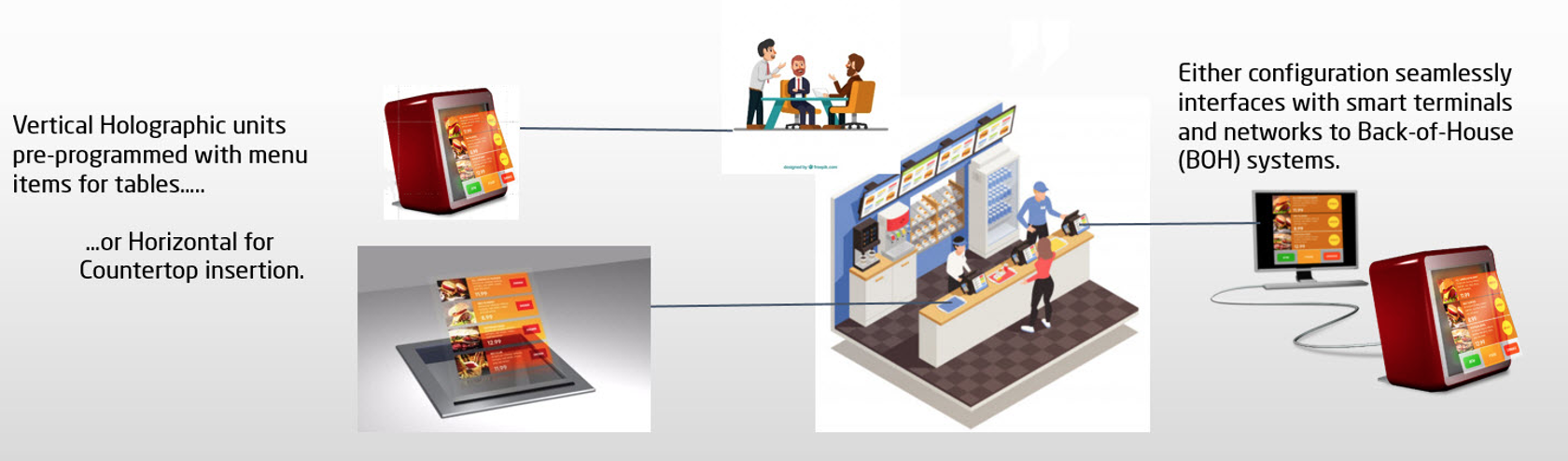

To demonstrate the difference between the two models, the diagram below depicts both configurations deployed in a fast-food restaurant. The “stand-alone” unit is pre-programmed with a series of menu items and inserted into tables or into counters. The tandem system is connected to the restaurant ordering terminal, and since Holo’s systems run on Windows 10 and Linux, connecting to Back-of-House programs, IoT, or other networks is seamless.

Holographic Touch: Beyond Covid-19

The range of applications includes: elevators, hotel registration systems, library book check-out systems, airplane galleys, coffee makers, vending machines, ATMs, retail stores, and more. Future applications include military/defense, automotive, aeronautics, medical, museums & events, gaming, whitegoods, consumer, industrial and entertainment.

Holo Industries is expanding their product line by investing heavily in peripherals and enhancements including adding: NFC, Wi-Fi, Biometrics, Haptics, Proximity Sensors, ePalm ID, Wake-on Approach, In-cabin monitoring, Sensory Feedback, IOT, CAN, Networking, Touch HUD, AI and more.

Summary:

While Holographic Touch was invented before the pandemic, it’s application as a safe, germ-free interactive media is an ideal solution: a large number of companies have discovered there is no substitute for mid-air interaction, and other remedies don’t come even come close as a Covid-19 solutions. As the world finds different ways to adjust to the “New Normal”, and social distancing and fear of interacting with touch surfaces evolves, Holographic Touch will remain as an exciting, versatile, and viable technology well into the future.

For more information: www.holoind.com