4 Benefits of Choosing a Filter Fan Enclosure Cooling Unit

June 10, 2024

The ability to cut through the complexity of modern manufacturing is a chief concern for companies across nearly every industry. This is due in large part to the diversification of the manufacturing landscape to include more uncontrolled or outdoor environments, but also because of the rapid growth in industries like material handling, automotive, and energy & power.

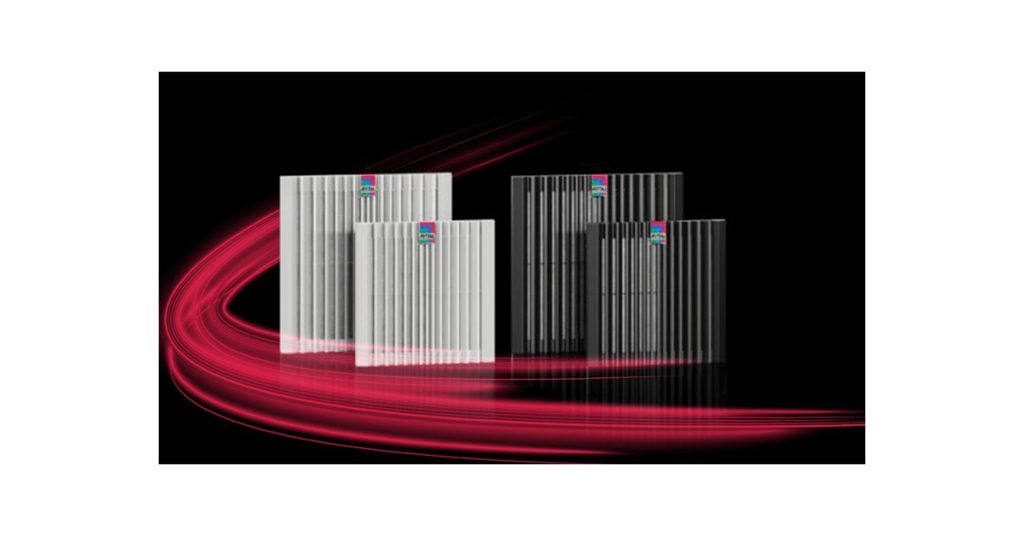

Filter fan industrial enclosure cooling units can help manufacturers leverage powerful cooling outputs that can meet the rigors of a range of industrial environments, while also helping to elevate their application versatility and configuration flexibility.

This article will look at four benefits of choosing a filter fan enclosure cooling unit, and how Rittal’s approach to these kinds of cooling systems can help manufacturers optimize their climate control processes to save time, money, and resources.

Streamlined cooling unit maintenance and upkeep

One of the biggest challenges manufacturers face is the time, tooling, and resources necessary to maintain or update their suite of industrial automation equipment. Not only can frequent maintenance intervals require a hefty investment of time and resources, it can also result in costly downtime — or, worse, unplanned gaps in production due to equipment failures or breakdowns.

This is especially applicable with enclosure cooling units and their ability to provide adequate, targeted cooling for prolonged periods. A streamlined, more efficient approach to maintenance can optimize cooling unit performance and increase the productivity of your production programs.

With filter fan units, filters can be quickly and easily replaced to maximize performance and uptime. The ability to streamline unit maintenance also helps save on material and equipment costs.

Rittal’s new Blue e+ Filter Fan EC cooling unit offers easy air filter changes via a new opening mechanism on the grille of the unit. The air filter can be accessed and swapped without the need for standard tooling, and easy access to the motor helps accelerate routine maintenance checks and servicing.

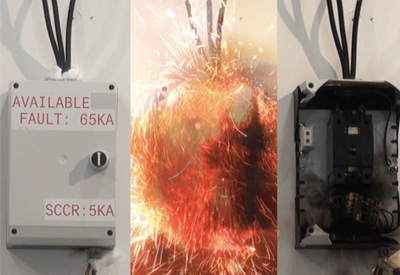

Filter fan enclosure cooling units can optimize cooling performance and outputs

Traditionally, filter fan units have not been able to provide the kind of targeted, powerful cooling outputs necessary to maintain optimal temperatures for enclosure performance and productivity. Another objection to these units is that achieving adequate cooling comes with sacrificing cost-effective, energy-efficient cooling.

However, the advancements in filter fan design and engineering — fueled in large part by IIoT and Industry 4.0 — have evolved this technology into an efficient, powerful method of enclosure cooling. Additionally, IIoT and Industry 4.0 have made it possible to equip filter fan units with monitoring capabilities to increase the flexibility of enclosure cooling programs.

The innovative design and engineering of the Blue e+ Filter Fan EC cooling unit prioritizes high-performance cooling via a pleated air filter that increases cool air movement and performance by 40%. The design of the Blue e+ Filter Fan’s motor also provides high-efficiency operation that can decrease energy costs by 60%.

Rittal’s new filter fan cooling unit uses Industry 4.0 and IIoT concepts to help manufacturers unlock more adaptive cooling. For example, an on-demand temperature control interface allows cooling to be monitored and adjusted in real-time.

Not only does this help manufacturers leverage more efficient, strategic enclosure climate control, it also helps increase the service life of the filter fan components by leveraging the ideal cooling outputs precisely when they’re needed.

Filter fan cooling units are designed for rapid installation

Installing, mounting, or integrating enclosure climate control units can be a cumbersome process that requires a large amount of time and resources to complete. This challenge is exacerbated by the sheer variety of custom automation systems manufacturers need to meet production demands, particularly in the case of retrofitting existing facilities for warehouse automation.

Automation assemblers and installers need simple, easy-to-install cooling units that don’t require specialized tooling or processes, and filter fan cooling units can provide the kind of rapid installation manufacturers need to reduce lead times.

Rittal’s new filter fan cooling units are equipped with simple, easy-to-use hooks for rapid installation on the enclosure itself. This also helps increase the rate at which manufacturers bring new automation systems online and makes it easier to scale automation infrastructure without sacrificing powerful cooling.

For manufacturers undergoing a retrofit process, Rittal’s filter fan units can be easily integrated into virtually any automation infrastructure without sacrificing performance.

Filter fan cooling offers more versatile enclosure climate control

The streamlined maintenance, simplified design and engineering, and rapid installation make filter fan cooling units a highly versatile enclosure climate control solution that can go virtually anywhere. What’s more, choosing a filter fan cooling unit with a multi-voltage capacity allows for seamless integration on a world stage, making it easier for manufacturers to accelerate their speed-to-market regardless of location.