GraceSense Case Study: Preventing Critical Breaker Failures and Extending Equipment Life Using Continuous Temperature Monitoring

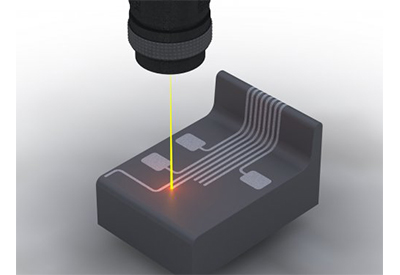

Excessive inrush currents combined with harmonics triggered by Variable Frequency Drives (VFDs) in large motor applications put severe thermal burden on electrical components that are connected in the system. These conditions often lead to unpredictable early failures in key electrical components such as circuit breakers, bus bars and other terminations.