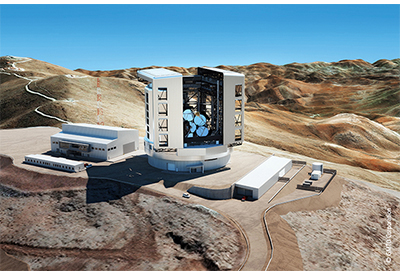

Giant Magellan Telescope With Site-Wide Real-Time Connectivity and 3,000 Precisely Controlled Servo Axes

The Giant Magellan Telescope (GMT) is a project of superlatives. After a long construction and planning period, the next-generation telescope is expected to go live in 2029. With seven mirrors and a combined diameter of 25 m, it will enable entirely new resolutions and even allow a look back into the time after the Big Bang. PC-based control from Beckhoff was specified as the future automation equipment.