Membrane switches for highly specialized HMI applications

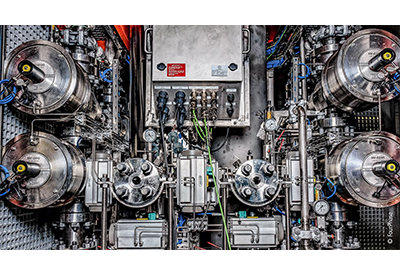

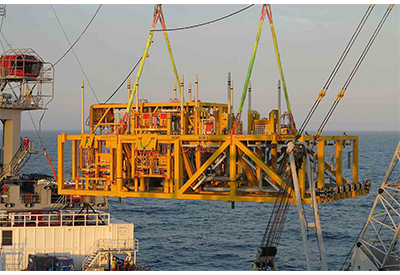

High-quality membrane switches are characterized by their reliability in all applications and their environmental conditions. Membrane switches used in highly specialized HMI applications such as in an industrial automation environment or for medical technology require more in-depth experience in development and design.