What Does Daisy Chaining Mean for Power Supplies?

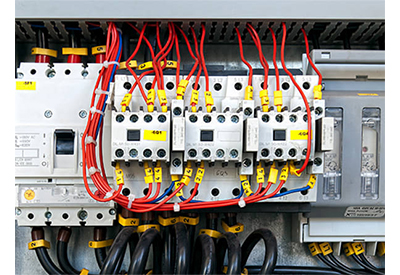

Daisy chaining refers to a wiring scheme in which several devices, such as power supplies, are connected directly in series. This type of wiring is also referred to as “looping through”. The English term “Daisy Chaining” is used colloquially, since the structure is vaguely reminiscent of a daisy chain. The principle can be used both to achieve a higher total current and to transmit analog signals or digital data.