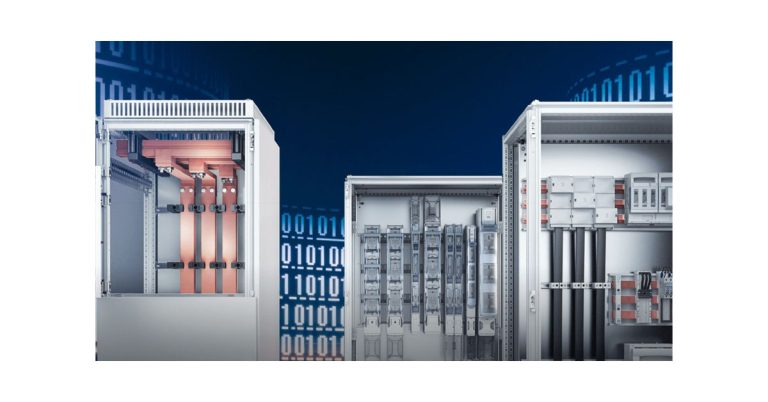

ABB Expands Centralized Protection and Control Offering to Address Aging Infrastructure; Future-Proof the Grid

REX615 is a technological leap forward from the 615 and 620 series relays, offering unparalleled flexibility, cost-effectiveness, and standardization. With its multiapplication coverage combined with fully modular and scalable hardware and software, REX615 picks up where its predecessors left off, ensuring users are poised for the grid of the future. “ABB understands the challenges the utility industry is facing and is committed to providing innovative electrical solutions that help utilities improve reliability, prevent outages and meet their sustainability goals,” says John Hayter, Vice President of Utilities Market, ABB Electrification.