UPS Systems Ensure Greater Reliability in Critical Infrastructures

February 5, 2025

In this blog article, you will learn why UPS systems are indispensable for ensuring a reliable and stable power supply in critical infrastructures, which components are needed for this, and which standards they must meet.

In the past 100 years, electricity has always flowed in one direction – from the producer to the consumer. However, new technologies, innovative ways of energy procurement and generation, as well as comprehensive digitalisation, are fundamentally changing the market. The successful integration of innovative components is crucial to actively shaping climate change and ensuring sustainable success.

The infrastructures for electricity, gas, water, and heat extend over vast supply areas and decentralized stations. Their smooth operation is of fundamental importance. Disruptions must be detected and resolved immediately, as they can have significant impacts on all areas of life within a short period. For this reason, these critical areas have been grouped under the term Critical Infrastructures (KRITIS).

KRITIS includes facilities and organisations whose failure or impairment can lead to significant supply shortages or disruptions to public safety. These infrastructures are essential for the functioning of society and include sectors such as energy, information technology, telecommunications, transport, health, and water.

Requirements for power supply systems in critical infrastructures

This blog article will examine the requirements for power supplies and DC UPS systems in critical infrastructures, as well as the relevant standards that play a role in this context.

Uninterruptible power supply (UPS) is indispensable in critical infrastructures. Energy supply companies use DC UPS systems in combination with remote control technology to protect the control systems of their power plants and to ensure the integration of renewable energies through transfer stations and distribution networks such as local secondary substations. The focus is on monitoring and controlling spatially remote objects.

Specific requirements for power supplies and UPS systems in critical infrastructures concern reliability, robustness, and security:

- Avoidance of downtime:

UPS systems ensure an uninterrupted power supply during power outages and enable an orderly shutdown of systems during prolonged outages. - Protection against voltage fluctuations:

UPS systems protect sensitive equipment from voltage fluctuations and power surges that could cause damage or data loss. This is essential for IT infrastructure and communication systems. - Increase in operational safety:

By providing a stable power supply, UPS systems contribute to overall operational safety and minimize the risk of operational interruptions. - Compliance with legal requirements:

Many critical infrastructures are legally required to take measures to ensure a continuous power supply. UPS systems help meet these requirements and ensure compliance with relevant standards and regulations.

Relevant standards and guidelines for critical infrastructures

The power supply in critical infrastructures is of paramount importance for the safety and well-being of society. By adhering to relevant standards and guidelines, operators can ensure that their systems function reliably and safely. Here are some of the most important ones:

- §14a EnWG: Regulates the grid-oriented control of controllable consumption devices and controllable grid connections.

- VDE-AR-N-4105: Technical minimum requirements for the connection and parallel operation of generation plants in the low-voltage network, a national standard for the grid connection of generation plants in low voltage.

- VDE-AR-N-4110: Forms the technical basis for the connection and operation of customer systems to the medium-voltage network.

- BSI-Kritisverordnung: This regulation defines which facilities are considered critical infrastructures and what security requirements they must meet.

Network operators are obligated to ensure a stable and reliable power supply. The grid must adapt to the increasingly flexible energy flow. Uneven consumption situations and generation, higher loads, and the feed-in of decentralized electricity cause voltage fluctuations.

Peak loads with unknown simultaneity factors pose a significant challenge. The following elements have the greatest impact:

- PV systems

- Heat pumps

- Battery storage

- E-mobility

These requirements from different perspectives, as well as the climate goals of the German federal government, lead to a massive expansion of the energy infrastructure. Experts expect that the energy supply infrastructure will need to be doubled to meet the climate goals.

The constantly growing share of renewable energies also contributes significantly to the strong growth in this sector. Current studies, such as the study by the Hans Böckler Foundation, predict a doubling of the investment volume in the coming years.

In demanding environmental conditions, the right hardware is crucial

The development of UPS systems for critical infrastructures is driven by technological innovations and the integration of new technologies. These trends help improve the reliability, efficiency, and safety of power supply in critical areas.

A significant trend is the introduction of modular UPS systems. These offer flexible and scalable solutions as they consist of several independent modules that can be added or removed as needed. This facilitates adaptation to growing demands and increases redundancy.

Additionally, UPS systems are increasingly being integrated into smart grids. This integration enables better monitoring and control of the power supply, which increases efficiency and reliability. Smart grids can also better incorporate renewable energy sources and improve grid stability.

Another important aspect is the retrofitting of existing infrastructure in local substations with so-called retrofit solutions. These solutions measure the outputs and provide data for extended network planning to take appropriate measures in case of failure. The installation situation of the devices is often challenging, as the standardized form factor of a load switch strip is frequently used as a housing specification.

Finally, there is a growing trend towards the development of environmentally friendly UPS technologies. This includes the use of renewable energies, the reduction of the carbon footprint, and the improvement of energy efficiency.

High ambient temperatures are the biggest “challenge”

PULS Group supports customers in finding optimal power supply solutions for the aforementioned requirements. The company places great emphasis on well-managed project planning and the easy integrability of it’s systems. The following properties are particularly important to customers: lifetime, size, and temperature range.

There are special requirements, especially regarding operating temperatures and the associated lifetime. The reason for this is the harsh environmental conditions often found in non-air-conditioned outdoor areas.

Let’s consider a “robust” environment with partial direct sunlight in a local substation and use the annual temperature profile of Tönisvorst (a city in North Rhine-Westphalia) from the year 2022. Here, the highest ever recorded outdoor temperature in Germany of 41.2 °C was registered. Such a high outdoor temperature means that temperatures of over 75 °C can occur in active local substations in Germany.

This maximum requirement forms the basis for the offset applied to the temperature profile to simulate the maximum load on the installed components. This means that a permanent load of over 70 °C is not assumed, but rather a temporary peak temperature on several days per year.

This detailed simulation is very useful, as the trend towards warmer years and higher peak values due to climate change is demonstrably present.

Software simulation helps in choosing the right components

To optimally specify it’s solutions for high temperatures, PULS conducted a detailed lifetime simulation at the component level using software. Based on the results and the requirement that the devices must achieve stable buffering of full performance for more than 10 years, the company selected the components and designed the corresponding circuitry.

To ensure reliable operation, it is crucial that the devices do not shut down even at temperatures above 70 °C. In the event of a necessary safety shutdown, they must also restart independently.

Heat has a negative impact on the lifetime and reliability of DC-UPS and power supplies

The minimum lifetime of DC-UPS and DIN rail power supplies is determined by the lifetime of electrolytic capacitors, which are the most critical element in the devices. Even a temperature increase of +10 °C in the power supply halves the lifetime of the capacitors.

To achieve the longest possible lifetime of DIN rail power supplies and DC-UPS, it is therefore important that the devices are protected from overheating. The cooling concept chosen during the development of the power supply plays a crucial role.

Ideally, the devices are designed to generate as little heat as possible from the outset. This is achieved through high efficiency and correspondingly low power losses. Since losses cannot be completely avoided, it is essential to efficiently dissipate the resulting heated air from the device.

Efficient cooling concept for long-lasting power supplies: The “Cool Design” by PULS

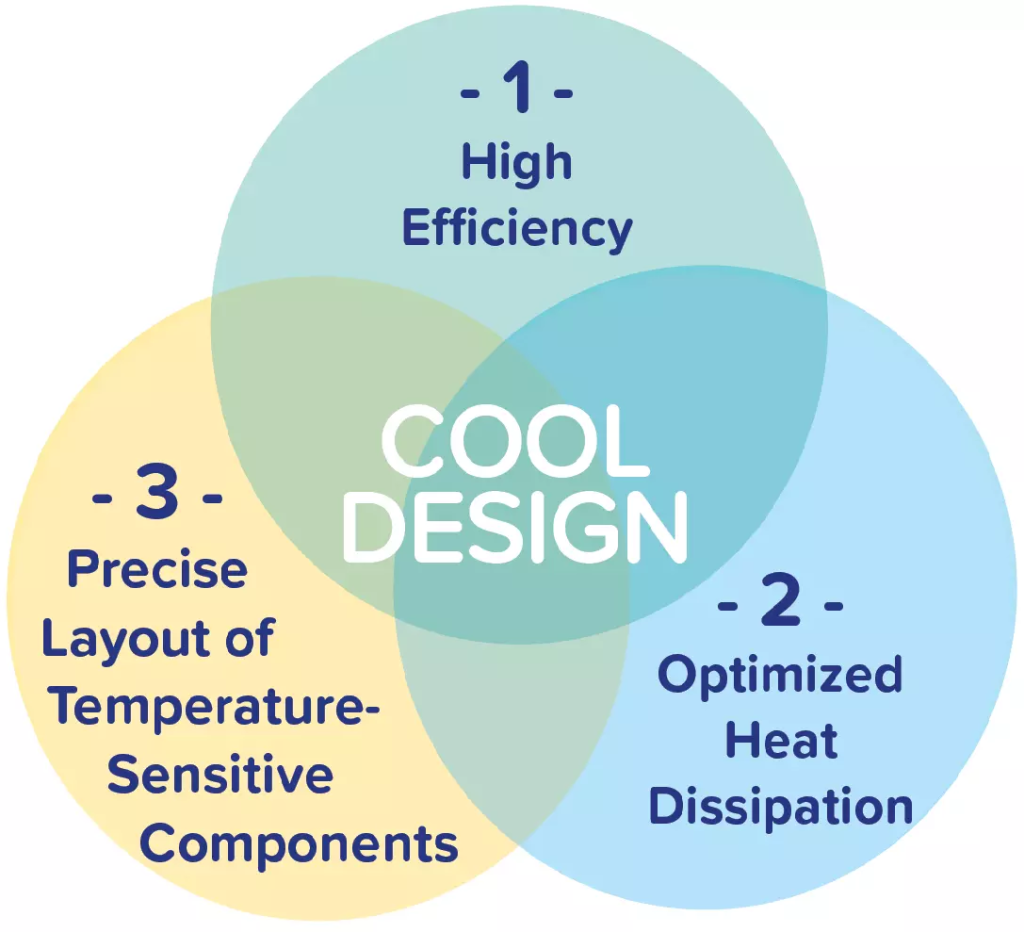

To ensure a long lifetime for power supplies, it is essential to minimize heat generation within the devices. With the “Cool Design” concept, PULS defines the interaction of three key factors that lead to low heat generation: firstly, consistently high efficiency; secondly, optimized dissipation of heat to the device’s surroundings; and thirdly, the thoughtful arrangement of temperature-sensitive components within the device.

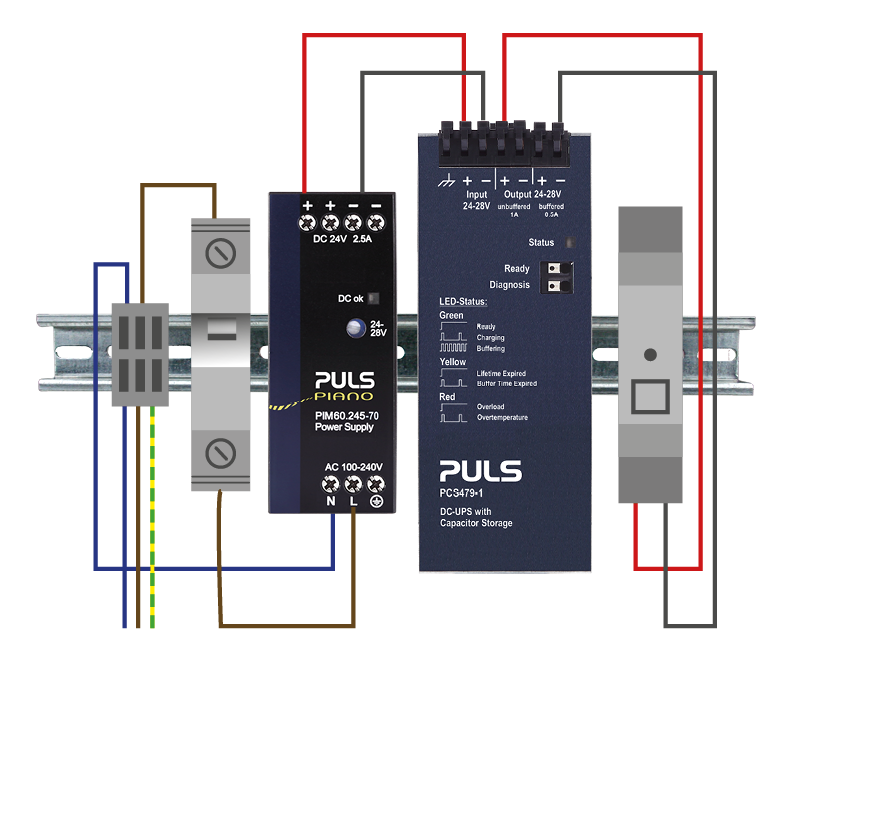

In terms of DC-UPS systems, PULS has so far pursued the approach of realising the power supply and the DC-UPS module with separate devices, rather than integrating both functions into one housing. This separates the power supply, as the primary heat source, from the sensitive electrolytic capacitors in the UPS module.

However, PULS’s latest subsidiary Adelsystem has been successfully offering an all-in-one solution for several years, combining a power supply and a DC-UPS in one device. The Italian developers have chosen a smart device concept for this approach, which we will discuss in a separate blog article.

DC-UPS – with battery or capacitor storage?

Currently, PULS offers two options for an uninterruptible power supply to the load in an emergency: both double-layer capacitors and lead-acid batteries can serve as energy storage in DC-UPS systems for industrial applications.

Double-layer capacitors, also known under trade names such as Ultracaps, Supercaps, or Greencaps, have been available on the market for over 25 years and have developed into reliable and proven components. These initially quite expensive components are suitable as energy storage for DC-UPS systems and can be used in applications such as storing braking energy or providing short peak currents.

Which energy storage solution is suitable for which application cannot be answered in general. Each application is individual and therefore requires a specific analysis to ensure the best possible uninterruptible power supply.

The following questions can help find the ideal backup solution for your system:

- What output voltage is required?

- How much current must be available as a reserve?

- How much backup time is required?

- Are there loads in this application that do not need backup, and if so, how many?

Based on this information, recommendations can be made for the required output power of the power supply, the backup method, and any additional devices that may be needed. Of course, proven standard combinations that are often used by customers and are typical for the industry also result from the corresponding requirements of the standard.

Summary:

Reliable power supply in critical infrastructures is of paramount importance for the safety and well-being of society. By adhering to relevant standards and guidelines, operators can ensure that their systems function safely. The use of modern technologies also allows for the benefits of renewable energies to be harnessed while addressing the associated challenges.

UPS systems are indispensable for ensuring a reliable and stable power supply in critical infrastructures. They protect against outages, voltage fluctuations, and data loss, thereby contributing to the safety and efficiency of operational processes. Implementing UPS systems in critical infrastructures is complex and requires careful planning and good consultation with the manufacturer. Despite these challenges, UPS systems are essential to guarantee the reliability and safety of power supply in critical areas.

Determining which UPS system is suitable for which application cannot be answered in general terms. Each application is unique and therefore requires a specific analysis. However, industry-specific application fields also define proven device combinations.

https://www.pulspower.com/us/blog/ups-systems-ensure-greater-reliability-in-critical-infrastructures