4 Things You Need to Know About Thermal Management for Enclosures

July 11, 2023

By Kooltronic Inc.

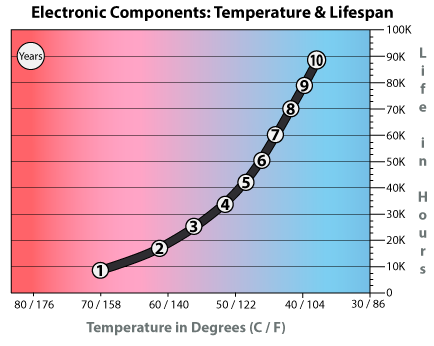

Thermal management helps control the temperature within a sealed enclosure to prevent electronic components from overheating. Although individual manufacturer’s specifications vary, most electrical distribution and control equipment operates longer and more effectively under ambient air conditions ranging from 104° – 122°F [40° – 50°C]. Temperatures that exceed this range can damage electronics, causing outages or permanent failure. In fact, every ten-degree rise in temperature shortens the average reliability of electronic equipment by 50%, so it’s important to have a reliable enclosure cooling system in place to protect heat-sensitive components.

In addition to helping prevent electrical system damage, thermal management also offers several benefits, such as:

Increased Lifespan & Reliability

Overheating is one of the leading causes of electrical equipment failure. Keeping components cool will extend their lifespan and improve their reliability. The chart below illustrates the benefits of increased longevity when an enclosure is properly cooled. For more details, read our whitepaper, Increasing the Lifespan & Reliability of Electronic Components.

Improved Performance

When electrical components operate at higher than recommended temperatures, they perform less efficiently. Regulating the operating temperature within an enclosure will help get the most out of the electronics or equipment being used.

Reduced Costs

Excess heat can lead to expensive repairs or replacement of electronic components. Also, lost revenue associated with process downtime can quickly add up. Investing in a good thermal management system will help avoid this costly downtime and save money in the long run.

Improved Safety

Overheating can often pose a safety hazard. If electrical devices overheat, they can catch fire or release harmful fumes. Keeping components cool can reduce the risk of these unexpected hazards.

It is important to think about cooling in the early stages of the design process. Investing in a high-quality thermal management system can improve the reliability, performance, and safety of electronic equipment. The best method for cooling an enclosure will vary depending on the specific components contained within a cabinet, the operating environment, and other factors. For guidance with product sizing and selection, try our free cooling calculator or contact an enclosure cooling expert.