How GFCIs Empower Panel Builders to Protect Against Electrical Shock and Save Lives

September 27, 2022

By: Littelfuse

With power, comes great responsibility. A panel builder who can effectively integrate ground-fault circuit interrupters (GFCIs) into a system can make the difference between life and death.

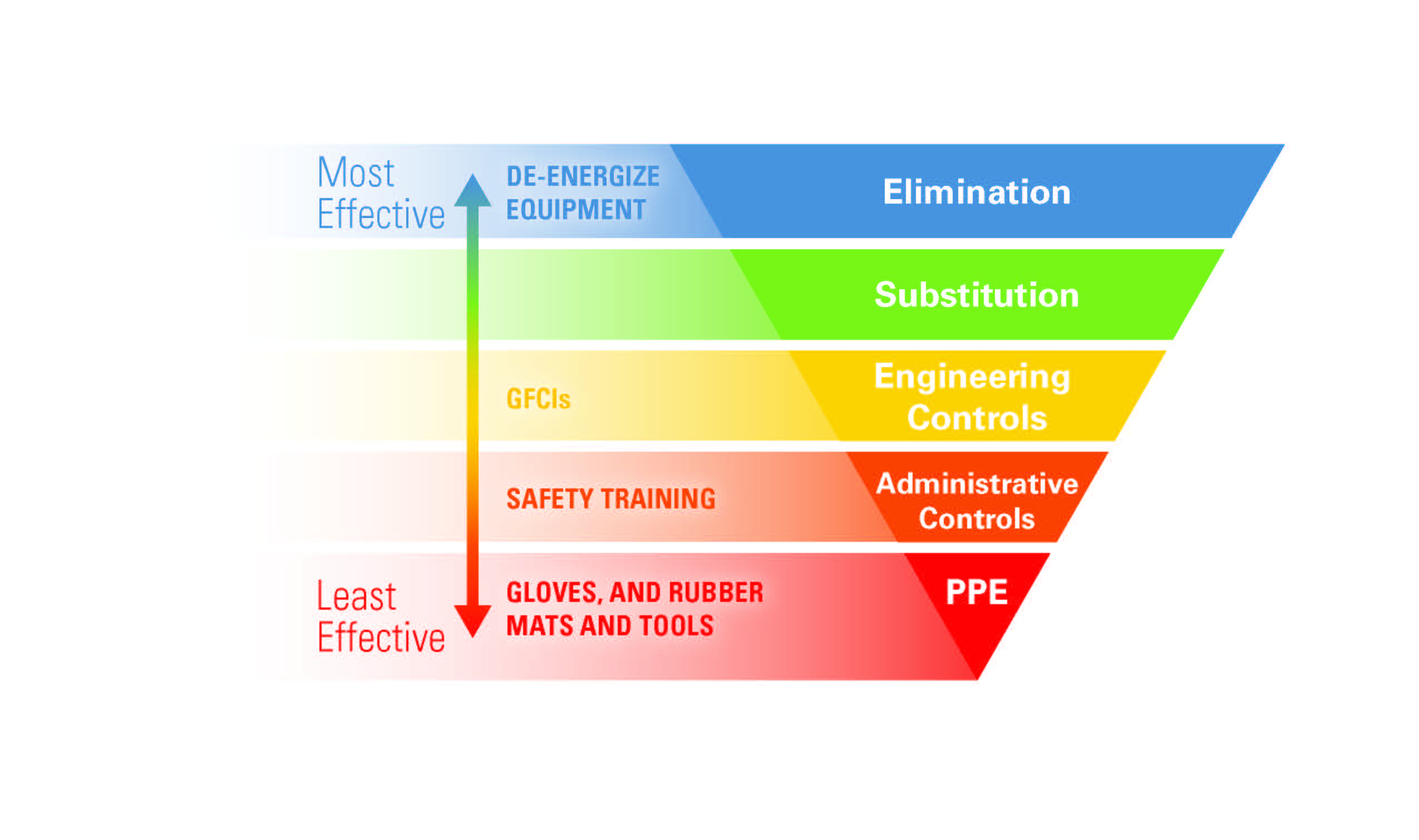

Ground-fault circuit protection is one of the most effective preventative measures against electrical shock because it actively reacts to irregular electrical conditions, regardless of a worker’s qualifications or use of personal protective equipment (PPE). This is because GFCIs are an out-of-sight-out-of-mind practice that require nothing from the worker to operate reliably.

Prevention through Design and GFCIs

GFCIs eliminate shock hazards by cutting off power when even the slightest amount of current flows where it should not. If a person touches a live GFCI-protected conductor, the GFCI will open the circuit before the shock incident becomes lethal.

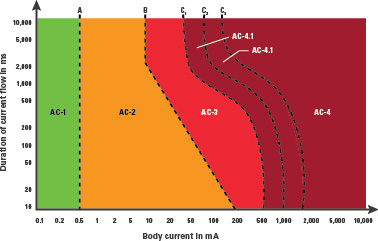

GFCIs limit the human body’s exposure to shock by interrupting the circuit before the magnitude of current and its duration poses the risk of ventricular fibrillation. The area shown as AC-2 in the figure below indicates where the threat of ventricular fibrillation is unlikely. GFCIs operate according to a curve that is faster, and more sensitive than the lagging edge of AC-2. If there is a 50-milliampere fault, then the GFCI will trip in 100 ms or less, keeping the person safe from heart fibrillation.

On the Prevention through Design pyramid, which orders the types of preventative measures you must take, GFCIs are considered an engineering control because, though the presence of shock hazards cannot be eliminated, you can use GFCIs to engineer the conditions to be an environment free from the hazard.

A single-phase GFCI contains a zero-sequence current transformer in which the hot and neutral lines pass through. Its sense winding feeds a triggering circuit that is connected to an interrupting device.

If there is no leakage to ground (through either bad insulation, a person, or both), then the currents in the hot and neutral lines will be equal and cancel each other out in the current transformer. However, if there is leakage (if some of the current that is going out on the hot conductor does not return through the neutral), then the two currents will no longer sum to zero and the sense circuit will trip the contactor to shut off the power.

GFCI classes and their applications, and special-purpose GFCIs

UL divides GFCIs into Classes A, C, D and E[1]. A GFCI’s trip threshold is determined by its class.

Class A GFCIs (non-residential)

Class A GFCIs, which are commonly used in residential and commercial settings, have a 6-milliampere trip level and are used in single- and three-phase systems with 150 V to ground (usually 120 V or 240 V for single-phase systems, and 208 V for three-phase systems). This includes both standard household GFCIs and commercial GFCIs that are used in restaurants, garages, and other non-residential applications.

Class A GFCIs are governed by UL 943, which applies to Class A, single- and three-phase GFCIs in accordance with the NEC, the Canadian Electrical Code (CE Code), and ANSI/NFPA 70. Class A GFCIs provide let-go protection and do not require equipment ground conductor monitoring.

Class C, D, and E GFCIs (special-purpose GFCIs)

Class C, D, and E GFCIs are all special-purpose GFCIs. Special-purpose GFCIs are used in industrial systems, typically those with voltages of 480 or 600 V line-to-line potential.

Special-purpose GFCIs trip when the leakage current exceeds 20 mA, or when the equipment ground conductor for that circuit is compromised. This higher trip level provides a greater flexibility for an industrial application, while still tripping fast enough to protect workers from a ventricular fibrillation event.

Ground monitoring is not required for the supply-side of permanently connected special-purpose GFCIs or when the load employs a system of double insulation.

Until 2009, GFCI protection was limited to single-phase ac circuits up to 240 V (150 V line-to-ground). However, because the hazards that GFCIs protect against extend beyond these applications, UL published UL 943C, which established three new classes of special-purpose GFCIs for systems up to 600 V.

Classes C, D, and E are governed by UL 943C, Special Purpose Ground-Fault Circuit-Interrupters. UL 943C addresses two limitations of Class A GFCIs that prohibit their use in many industrial applications: the system voltage limitation to a maximum of 240 V and a maximum allowed leakage current of 6 mA.

Class C devices are rated for phase-to-ground voltages of 300 V and less (480-volt 3-phase applications), while Class D and E cover applications greater than 300 V line-to-ground (600-volt 3-phase applications).

Class C devices are permitted to have a trip threshold as low as 6 mA. UL 943C requires the GFCI to monitor the continuity of the ground wire and interrupt power to the load if ground integrity is lost.

- Class C GFCIs: for use in circuits with no conductor over 300 V to ground where reliable equipment grounding or double insulation is provided. Class C GFCIs interrupt the circuit when the ground-fault current is between 15 mA and 20 mA. They have trip thresholds between 6 mA and 20 mA, which provides limited let-go protection.

- Class D GFCIs: for use in circuits with one or more conductors over 300 V to ground, and with specially sized reliable grounding to provide a low impedance path so that the voltage across the body during a fault does not exceed 150 V. Class D GFCIs interrupt the circuit when the ground-fault current is between 15 mA and 20 mA.

- Class E GFCIs: for use in circuits with one or more conductors over 300 V to ground but with conventional equipment grounding provided for the protected equipment in the system or with double insulation. Class E GFCIs interrupt the circuit when the ground-fault current is between 15 mA and 20 mA and require high-speed tripping for fault currents 300 mA and above.

All special-purpose GFCIs are required to monitor the ground conductor unless the load employs a system of double insulation. Ground conductor monitoring is always required for Class D devices since they are not subject to the double insulation exemption.

Special-purpose GFCIs are specifically designed to protect people from electrical shock in industrial and commercial applications due to their higher trip levels. Models like the Littelfuse Shock Block SB6100 have built-in overcurrent protection from Class T fuses. The load can be single-phase (line-to-line) or three-phase (without a neutral). The Shock Block SB6100 can used as a GFCI (with a fixed 20-milliampere trip level) or as an equipment ground-fault protective device (EGFPD), (can be adjusted as low as 6 mA, or from 10 mA to 100 mA in increments of 10).

Some manufacturers offer carts that are specifically designed to deliver GFCI protection to temporary installations.

1) There are also Class B GFCIs, but they are rare—if not obsolete—because they are only for use in pool light fixtures installed before 1965)

Proactive GFCIs Detect Ground Faults and Protect Against Fatal Shocks with One Device

Ground check tremendously increases safety. Ground check monitors the continuity of the grounding circuit, causing the power conductors to be de-energized if ground continuity is lost.

Ground conductor monitoring enhances the standard protection of a GFCI by taking proactive measures. A ground check feature provides this by preventing energization to a load with improper grounding, and by de-energizing any circuit where the grounding becomes compromised under load. By decreasing these hazardous situations, the probability of a person becoming part of the ground conductor circuit is far less likely.

Ground check is required for anyone using a Class C GFCI with a conventional ground conductor and though highly recommended, is optional for Class A GFCIs. Some of the better GFCIs have a ground check feature integrated into Class A and Class C models, making this extra layer of protection available, regardless of whether it is required or not.

A GFCI that can detect ground faults is not only beneficial due to the time it saves in replacing the burden of an assured grounding program, but in its ability to provide shock protection as well.

Equipment ground-fault protection devices and nuisance tripping

For some applications, 20 mA can be too sensitive (particularly if there are variable frequency drives present). Equipment ground-fault protection devices (EGFPDs) are similar to special-purpose GFCIs and operate on the same inverse time curve as other GFCIs listed to UL 943 and UL 943C. Whereas GFCIs protect people, EGFPDs are designed to protect equipment. EGFPDs are oftentimes the best option when the normal ground leakage exceeds the industrial GFCI’s 20-milliampere trip level.

A good EGFPD will have an adjustable sensitivity, which is usually between 6 mA and 100 mA. This enables the sensitivity to be adjusted to the lowest sensitivity level above the base leakage current. This creates the safest possible conditions for workers in environments where worker protection at 20 mA is not possible. Good EGFPDs can monitor the ground conductor, which—though not required by UL 943C—provide an additional layer of protection.

How to apply industrial GFCIs

Industrial GFCIs can be used on equipment subject to wash-down cleaning, process equipment that handles wet material, equipment that comes into frequent contact with workers or for portable electric equipment used outside, where long power cords and less robust temporary connections may be exposed to rain and moisture.

Panel builders can integrate industrial GFCIs, or the GFCI can be installed in an electrical cabinet such as a motor control center. They are also available with their own enclosures for mounting to the side of a machine or a wall.

The wiring is simple: attach source power on one side and the load circuit on the other side. In addition, there may be signal wiring for optional alarm communication.

Some models are equipped with built-in overcurrent protection (usually a fuse), which allows for a high interrupting rating (50 kA in some cases). This protects the internal contactor from damage and does not require the user to install a current-limiting device upstream of the industrial GFCI. Some models also offer undervoltage and chatter detection.

Conclusion

Electrical systems should always be designed with safety in mind, which empowers panel builders to prevent injuries and save lives. GFCIs are integral to electrical safety, and, thanks to technological advancements, they can protect areas beyond 120-volt levels.

Earlier this year, Littelfuse published a paper the dives deeper into this subject, which you can read here.