Fischer Family Creates Technology Group Conextivity

May 31, 2022

The Fischer family founded Conextivity Group to meet the connectivity challenge posed by the emergence of new cross-functional and scalable ecosystems, from locally interconnected devices and sensors to cloudmanaged IoT platforms. The group’s R&D department, which has doubled in size over the last five years, is strengthening its teams with new expertise, especially in signal integrity engineering, embedded electronics, the cloud and the IoT. The family-owned technology group is accelerating the development of its two business activities, Fischer Connectors and Wearin’, towards the same entrepreneurial vision. The former is broadening its scope of activity to include electronics and building a production site in Portugal. Wearin’ is expanding its IoT solution and signing technology partnerships to improve the safety and efficiency of the connected human; in May, it was at the heart of a European civil protection exercise to test technologies available to first responders in the event of large-scale disasters. With double-digit annual growth, Conextivity Group is aiming for a billion Swiss francs in revenue within 10 years.

‘Conextivity’: the family group’s new identity denotes an ambitious entrepreneurial and technological vision, since it refers to the future of connectivity (next) that Fischer Connectors and Wearin’ are cocreating (co/con, ‘with’) in partnership with their customers.

With this vision, summarized by the motto ‘Reimagining Connectivity’, the family-owned company, founded in 1954, is transforming itself from a connector supplier into a full-service partner for high-performance connectivity.

The connectivity challenge to be met

With its two business activities, Fischer Connectors and Wearin’, Conextivity Group offers a suite of products, solutions and services that span the entire connectivity value chain.

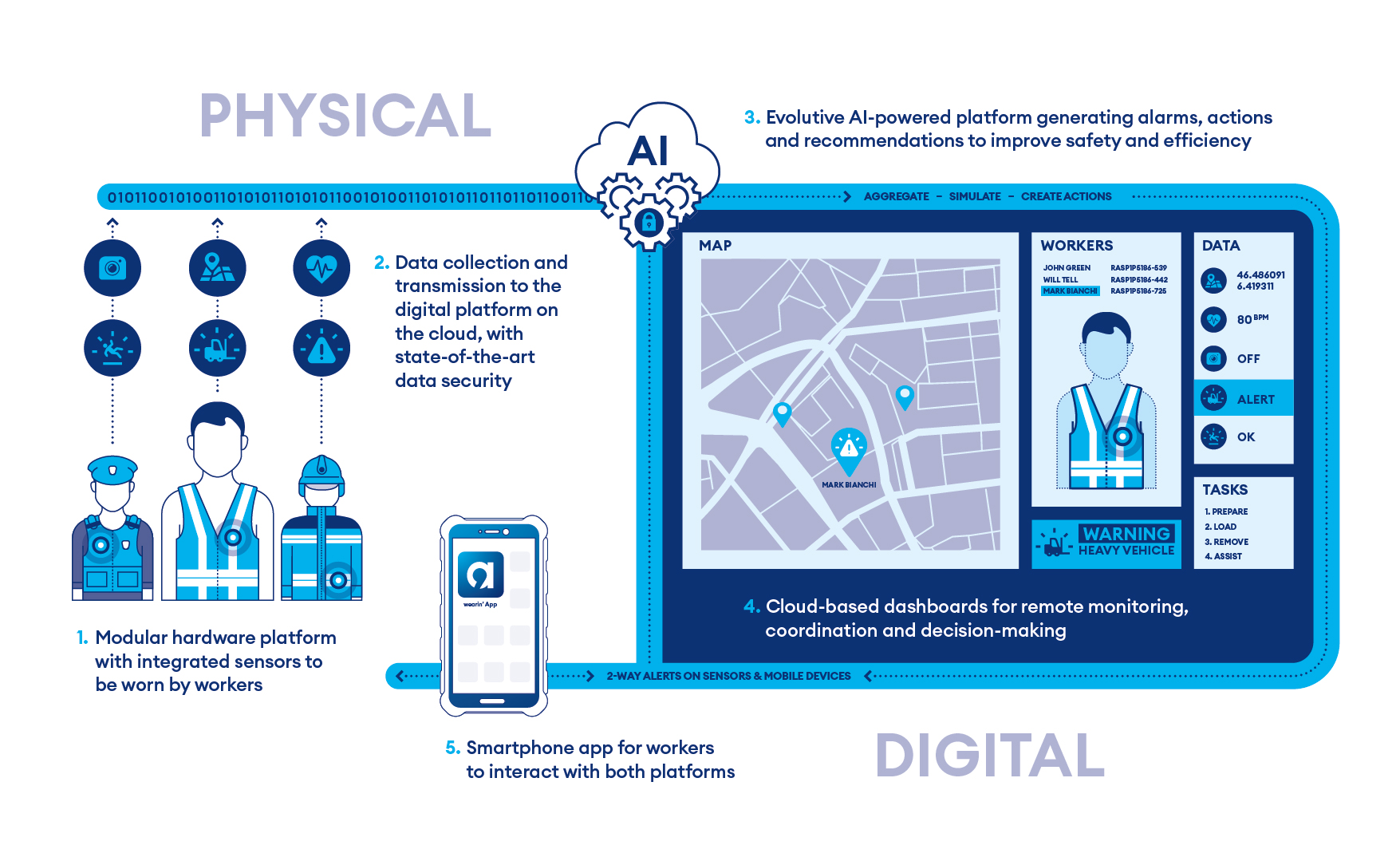

The goal is to meet the challenge posed by the rise of ubiquitous connected devices and sensors. These generate massive and exponential amounts of data and information to support decision making, especially in mission-critical applications as well as in the Internet of Things (IoT). The first technology challenge is to integrate end-to-end connectivity that not only establishes the physical connection between sensors and communication devices that need to be interoperable in increasingly demanding environments. In addition, there is the challenge of optimizing and harmonizing power and data flows at increasingly high performance and speed, and transmitting these data to the cloud infrastructures that enable them to be processed.

This combination of requirements in terms of performance, reliability, robustness and interoperability applies in particular in the cross-functional and scalable ecosystems found in mission-critical industries such as defense and security, medical, high-precision test and measurement instrumentation, robotics, first responders and wearables for the connected human.

System-level engineering

Solving the connectivity equation in these demanding environments requires a system-level engineering approach. This comprehensive approach enables the customer’s entire ecosystem to operate seamlessly and reliably. Optimized power and data flow performance and signal integrity are ensured throughout the connectivity chain, from connectors, cables, transmitters, receivers and electronics in locally connected devices to embedded software operating on physical and/or digital IoT platforms in the cloud.

“Connectivity is of crucial importance in our hyper-connected world,” explains Jonathan Brossard, CEO since 2016 and belonging to the 3rd generation of the Fischer family. “When it is as efficient, reliable and innovative as ours, and when it is applicable to extremely demanding operating environments, it plays a critical role. In this respect, our system-level engineering approach and our holistic vision for our industry expresses nothing less than our sense of responsibility: to reimagine connectivity that creates lasting value in the group’s traditional and new markets.”

Conextivity Group is aiming for a revenue of one billion Swiss francs within 10 years. To increase its commercial responsiveness on both global and regional levels, the group is continuing to invest in its industrial facilities and its research and development teams. Spread over four centers around the world, R&D has doubled its workforce in the last five years and has acquired new business expertise, particularly in signal integrity engineering, embedded electronics, the cloud and the IoT.

The family group is unveiling its new identity and technological vision to the public at a time when its R&D and commercial departments are accelerating the developments and deployments of Fischer Connectors and Wearin’.

For Fischer Connectors, scope of activity extended to include electronics

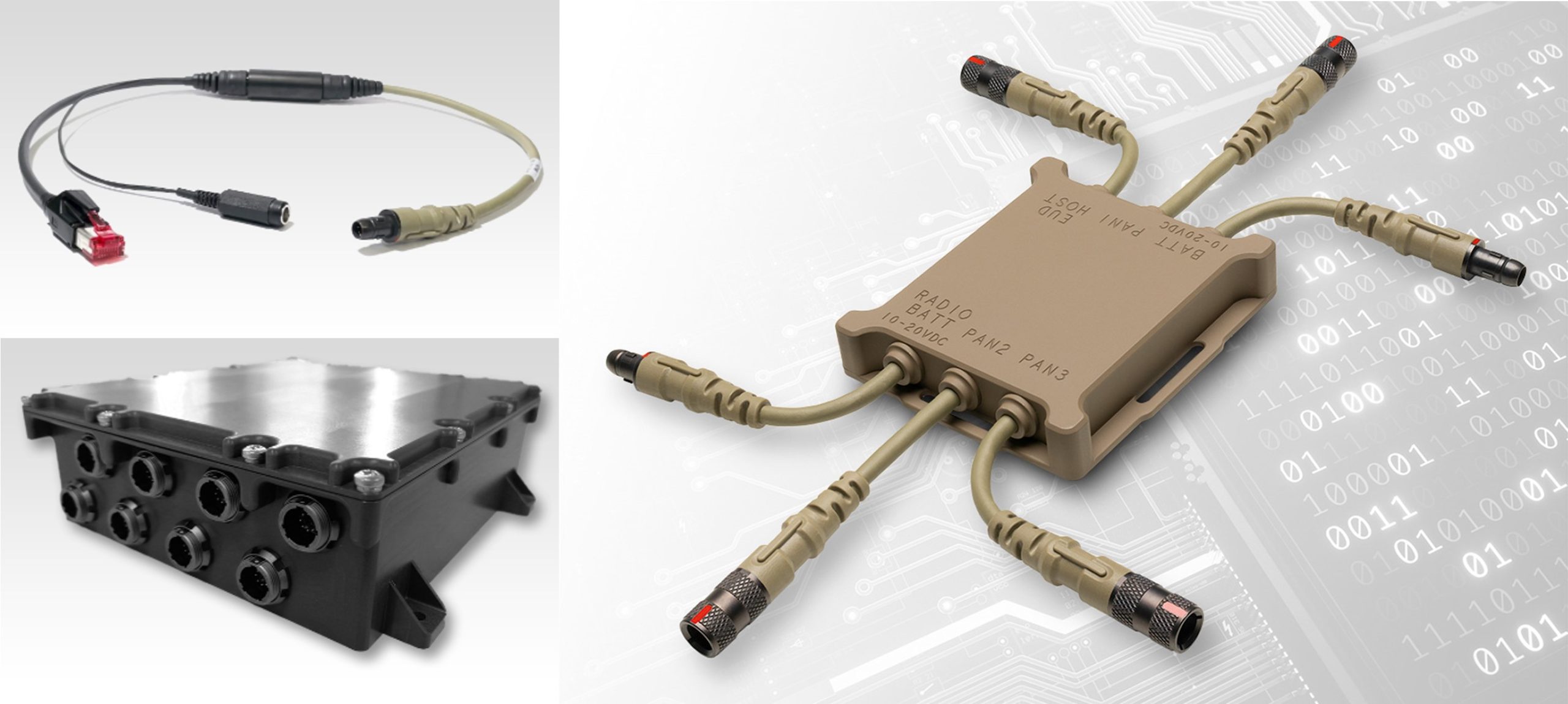

Fischer Connectors is extending its traditional business of high-performance connectors and cable assemblies into electronics. The company behind the world’s first hermetically sealed connector now offers tailored and pre-integrated electronic solutions as diverse as adapters, switches and tactical hubs. This expanded offering enables the seamless, end-to-end transfer and management of power and data flows in ecosystems operating locally under some of the industry’s most demanding technical, environmental and regulatory constraints.

Fischer Connectors is also continuing its international expansion and is increasing its operational capacity by building a new production site in Portugal. As soon as it is operational in 2023, the site will employ approximately 100 people in the first phase. In parallel, the group’s plant and world headquarters in Saint- Prex in Switzerland (canton of Vaud) is progressively turning itself into a center of excellence to maximize its technological and commercial response to complex, high value-added customer projects.

For Wearin’, deployment of technology partnerships

With a strengthened engineering team installed on its new premises in Morges (Vaud, Switzerland), Wearin’ has, since its creation in 2019, enhanced and perfected its IoT solution for the connected human.

In March 2022, it signed a memorandum of understanding with Airbus Secure Land Communications (SLC) to combine their technologies with a view to improving the safety and coordination of field response personnel. New partnerships are underway to be implemented in Wearin’s core markets: police and security forces, firefighters, first responders, and lone workers in logistics or construction.

From May 17 to 19, Wearin’s solution featured at the heart of the ‘Domino FSX’ civil protection exercise organized at European level by the French Ministry of the Interior to test technologies and the chain of command for first responders in the event of full-scale (FSX) disasters. The artificial intelligence developed by Wearin’ makes it possible to use the data collected by biometric and gas detection sensors worn by first responders in the field, to generate automatic alerts that complement the real-time data displayed on the dashboards of the command center coordinating the operations.

Unique in both its technological ingenuity and modularity, its solution makes high-risk work environments safer and smarter. Data from biometric sensors and environmental detection alarm systems worn by users in the field provide comprehensive real-time situational awareness to a central monitoring station. Via a cloudbased dashboard platform powered by artificial intelligence, the central station can communicate real-time information and recommendations that improve safety, efficiency and the collective coordination of ongoing operations and responses.

![]()