Metric Vs. AWG Size Conductors

More than crude oil is extracted from oilfields. Naturally occurring water—or “produced water”—is a byproduct that must be managed in an environmentally compliant way. A key partner in recycling produced water is Endpoint Industrial Controls. Headquartered in Loveland, Colorado, the company is part of the Rockwell Automation PartnerNetwork program and uses Rockwell technologies to create end customer solutions.

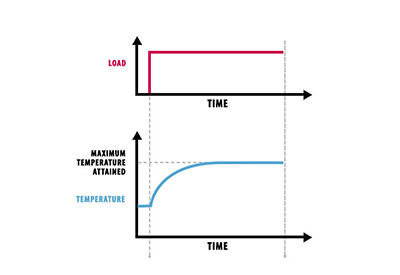

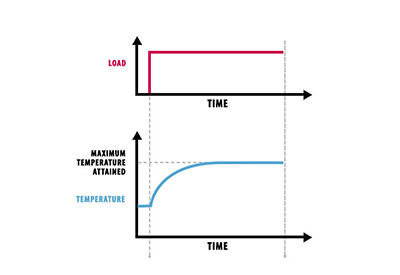

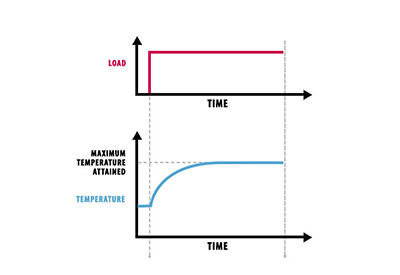

When selecting a motor, it is important to consider the required duty cycle to ensure the motor can meet the needs of the application. This blog post and the accompanying light board video will provide a basic introduction to motor duty cycles and a few of the most common types of duty cycles.

A digital twin is a virtual representation of an object or system that contain real-time data and information that allow engineers to assess a design without the need for a real-world object. This digital version can be used to measure, analyze, predict, control, or optimize its placement in the physical world – i.e., during product development or inspection, and postproduction to enable effective troubleshooting while minimizing downtime.

Eaton experts explain how to thoughtfully embrace Industry 4.0 technologies, sharing strategies, considerations, and personal examples to help ensure that your foray into Industry 4.0 starts out on the right foot. It’s been exciting to see the full potential of the Fourth Industrial Revolution, or Industry 4.0, go from concept to reality. This era’s immediate predecessor, Industry 3.0, represented a quantum leap in manufacturing productivity and efficiency.

RS Group plc offers more than 4,900 fully customizable electrical and electronic enclosures from Hammond Manufacturing, in addition more than 2,900 supporting products. Enclosures are used to connect and protect two or more electrical and electronic components and devices. They are employed in virtually every commercial and industrial application, and every enclosure gets modified in some way. The simplest enclosures, junction boxes, have just a couple of holes cut for input and output wires, while more complex enclosures can have holes cut for connectors, displays, and other components and can even be silkscreened, molded in a special color, and fabricated to a special size.

How can innovation processes be transformed to make the best possible use of the Fourth Industrial Revolution’s potential? How can companies identify domain- or technology-specific issues that can be replicated across sites or domains with the objective of revolutionizing whole industries? The author of a new book on tomorrow’s technologies and business strategies explains.

More than crude oil is extracted from oilfields. Naturally occurring water—or “produced water”—is a byproduct that must be managed in an environmentally compliant way. A key partner in recycling produced water is Endpoint Industrial Controls. Headquartered in Loveland, Colorado, the company is part of the Rockwell Automation PartnerNetwork program and uses Rockwell technologies to create end customer solutions.

When selecting a motor, it is important to consider the required duty cycle to ensure the motor can meet the needs of the application. This blog post and the accompanying light board video will provide a basic introduction to motor duty cycles and a few of the most common types of duty cycles.

A digital twin is a virtual representation of an object or system that contain real-time data and information that allow engineers to assess a design without the need for a real-world object. This digital version can be used to measure, analyze, predict, control, or optimize its placement in the physical world – i.e., during product development or inspection, and postproduction to enable effective troubleshooting while minimizing downtime.

Eaton experts explain how to thoughtfully embrace Industry 4.0 technologies, sharing strategies, considerations, and personal examples to help ensure that your foray into Industry 4.0 starts out on the right foot. It’s been exciting to see the full potential of the Fourth Industrial Revolution, or Industry 4.0, go from concept to reality. This era’s immediate predecessor, Industry 3.0, represented a quantum leap in manufacturing productivity and efficiency.

RS Group plc offers more than 4,900 fully customizable electrical and electronic enclosures from Hammond Manufacturing, in addition more than 2,900 supporting products. Enclosures are used to connect and protect two or more electrical and electronic components and devices. They are employed in virtually every commercial and industrial application, and every enclosure gets modified in some way. The simplest enclosures, junction boxes, have just a couple of holes cut for input and output wires, while more complex enclosures can have holes cut for connectors, displays, and other components and can even be silkscreened, molded in a special color, and fabricated to a special size.

How can innovation processes be transformed to make the best possible use of the Fourth Industrial Revolution’s potential? How can companies identify domain- or technology-specific issues that can be replicated across sites or domains with the objective of revolutionizing whole industries? The author of a new book on tomorrow’s technologies and business strategies explains.

More than crude oil is extracted from oilfields. Naturally occurring water—or “produced water”—is a byproduct that must be managed in an environmentally compliant way. A key partner in recycling produced water is Endpoint Industrial Controls. Headquartered in Loveland, Colorado, the company is part of the Rockwell Automation PartnerNetwork program and uses Rockwell technologies to create end customer solutions.

When selecting a motor, it is important to consider the required duty cycle to ensure the motor can meet the needs of the application. This blog post and the accompanying light board video will provide a basic introduction to motor duty cycles and a few of the most common types of duty cycles.

A digital twin is a virtual representation of an object or system that contain real-time data and information that allow engineers to assess a design without the need for a real-world object. This digital version can be used to measure, analyze, predict, control, or optimize its placement in the physical world – i.e., during product development or inspection, and postproduction to enable effective troubleshooting while minimizing downtime.

Eaton experts explain how to thoughtfully embrace Industry 4.0 technologies, sharing strategies, considerations, and personal examples to help ensure that your foray into Industry 4.0 starts out on the right foot. It’s been exciting to see the full potential of the Fourth Industrial Revolution, or Industry 4.0, go from concept to reality. This era’s immediate predecessor, Industry 3.0, represented a quantum leap in manufacturing productivity and efficiency.

RS Group plc offers more than 4,900 fully customizable electrical and electronic enclosures from Hammond Manufacturing, in addition more than 2,900 supporting products. Enclosures are used to connect and protect two or more electrical and electronic components and devices. They are employed in virtually every commercial and industrial application, and every enclosure gets modified in some way. The simplest enclosures, junction boxes, have just a couple of holes cut for input and output wires, while more complex enclosures can have holes cut for connectors, displays, and other components and can even be silkscreened, molded in a special color, and fabricated to a special size.

How can innovation processes be transformed to make the best possible use of the Fourth Industrial Revolution’s potential? How can companies identify domain- or technology-specific issues that can be replicated across sites or domains with the objective of revolutionizing whole industries? The author of a new book on tomorrow’s technologies and business strategies explains.

This webinar presented by Beth Lessard and Keith Cordero will be highlighting three Panduit solutions that will optimize network equipment and cabling to ensure that your spaces are efficiently and properly managed to support ever-evolving business needs of today and beyond. Products that will be featured include PanZone TrueEdge Wall Mount Enclsoure, Cable Managers, and Adjustable Depth 4-Post Rack.

The Siemens SIMOVAC medium-voltage non-arc-resistant and SIMOVAC-AR arc-resistant controllers have a modular design incorporating up to two 12SVC400 (400 A) controllers, housed in a freestanding sheet steel enclosure. Each controller is UL 347 class E2, equipped with three current-limiting fuses, a non-load-break isolating switch, and a fixed-mounted vacuum contactor (plug-in type optional for 12SVC400). The enclosure is designed for front access, allowing the equipment to be located with the rear of the equipment close to a non-combustible wall.

Power is vital to production, and well-designed control cabinets are key. Allied Electronics & Automation offers a comprehensive collection of control cabinet solutions including PLCs, HMIs, contactors, miniature circuit breakers, terminal block connectors, DIN-rail power supplies, pushbutton switches, motor starters, overloads, power relays, industrial Ethernet switches and AC drives engineered to keep your operations running safely, reliably and efficiently.

Learn more HERE.

OKW has extended its RAILTEC B range of DIN rail enclosures by adding the BP M22, a new panel version with pluggable front and side panels. RAILTEC BP M22 can accommodate plug headers (maximum 1 or 2 x 16-pin, 5.08, fixed or pluggable). It is ideal for a wide range of applications, notably individual DIN-rail-mounted… Read More…

METCASE has launched TECHNOMET TX, an elegant new range of premium tower enclosures for tabletop electronic instrumentation. With a space-saving footprint to maximise workstation space, these smart new aluminum enclosures are ideal for test and measurement, industrial control, medical/wellness, peripheral devices and interfaces, communications and laboratory equipment. Read More…