BRX PLCs Are Do-More Driven: 10 Ways It’s Better With BRX PLCs

December 23, 2020

1. Value that’s hard to believe, starting at just $197.00

What would you expect to pay for a PLC with built-in data logging, integrated motion control, customizable communications ports, and expansion capabilities? If you said a few thousand, then you are definitely in the right place. If you said a few hundred, then you’ve been here before! The BRX PLC platform, with the proven Do-more! DM1 technology, raises the bar on getting the most out of your PLC dollar. Whether you need a little (a simple communications controller with no on-board I/O) or a lot (36 built-in I/O points with motion, analog and expansion), the BRX family of PLCs will deliver outstanding features and ease-of-use at an unbelievable price.

Don’t forget with BRX PLCs you also get FREE software, FREE award-winning tech support, FREE shipping and FREE PLC training. You wont find this much value anywhere else!

- – Data logging

- – Motion capability

- – FREE Programming software with simulator

- – Hot swappable comm ports

- – Built-in high-speed I/O

- – Rest API for seamless integration with IT systems

- – Embedded Web server

- – Plus much more

2. Free industry-proven software

The FREE Do-more Designer programming software was developed and is supported in the U.S. and was designed to be powerful, flexible and easy to use. The user-friendly, fill-in-the-blank design makes complex operations like PID and motion control a cinch. It’s available to download online whenever you choose, however many times you’d like. Take it for a spin or start your project immediately, there are never any licensing fees or service charges.

3. Customized communication

With the BRX PLC platform you can choose which communications ports you need. All BRX PLC base units come with a built-in RS232C/485 software-selectable serial port, with an optional RJ45, 10/100Mbps Ethernet port on select units.

Protocols supported:

- – MQTT / MQTTS

- – HTTP / HTTPS

- – FTP (Client)

- – EtherNet/IP: Explicit (Client, Server), Implicit (Server)

- – Modbus RTU Master/Slave

- – Modbus TCP

- – SMTP (Email)

- – SNTP (Time Server)

- – TCP/IP

- – DHCP

- – Ethernet remote I/O

- – K-sequence Slave

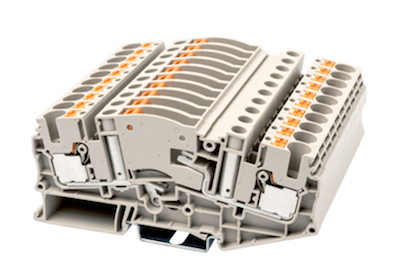

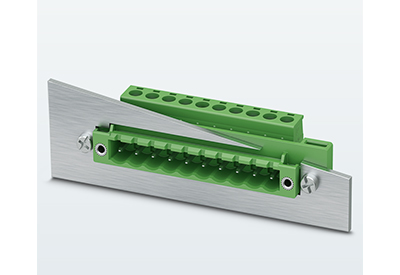

In addition, all BRX base units have a slot in the CPU that allows for an additional user-selected communications port. These user-selected ports are called Pluggable Option Modules (POMs) and come in 3-pin serial RS232, RJ12 serial RS232, 3-pin serial RS485, 5-pin serial RS232 with flow control, 5-pin serial RS422, USB and Ethernet versions. Simply choose the port you want, install it and go!

With support for MQTT / MQTTS, HTTP / HTTPS, FTP (Client), Ethernet/IP: Explicit (Client, Server), Implicit (Server), Modbus RTU Master/Slave, Modbus TCP, SMTP (Email), SNTP (Time Server), TCP/IP, DHCP, Ethernet remote I/O, K-sequence Slave, the BRX PLC family provides supreme communications versatility for any application.

4. Integrated motion on multiple levels

Motion with BRX PLCs can be as easy or sophisticated as you need. Three levels of instruction complexity allow you to choose the degree of customization involved with your motion control application. Choose the zero complexity option with minimal user input, the intermediate level for more user-defined features, or the advanced level to create custom move profiles. And with the built-in high-speed I/O, the BRX platform takes practical motion to a whole new level.

5. Built-in data handling and storage

Data collection is becoming one of the most important functions of a control system and with the BRX PLC family, data logging is included free of charge. The BRX CPUs come standard with 1MB of internal RAM for data logging plus up to 32GB of data storage on an optional, removable microSD card. The BRX platform also integrates many data-centric instructions for custom data logging and file handling operations.

6. Flexible hardware to meet your needs

The BRX PLC family uses the popular Do-more! DM1 technology and is an extremely versatile compact stackable system that you can customize to your specific controller needs. With four different form factors, built-in high-speed inputs, interchangeable communications port, on-board analog I/O, and many I/O expansion modules available, you can build the ideal controller for your application.

See what BRX is all about in the video below.

{videobox}kIB48Z3PGgI{/videobox}

7. Timesaving PLC simulator included for free

There is no better time-saver than the FREE PLC simulator in the Do-more Designer software. Use it to test your system code without the hardware present, verify the effects of code changes before implementation, replicate fault conditions to test code stability, or try out new programming techniques/methods for greater efficiency.

8. Trouble-free troubleshooting

When problems arise, fix them fast with the easy-to-use troubleshooting tools designed into the Do-more Designer software. See real-time trending data with the Trend View, execute the program one step at a time with the Debug View, or get diagnostic data remotely anytime via the embedded web server. These and other integrated software tools help save you troubleshooting time and alleviate frustration.

9. Industry 4.0 and IIoT ready

With Industry 4.0 and the IIoT, today’s modern systems are more connected than ever before with access to tons of new data on the world wide web. With BRX PLC’s built-in connectivity, you can harness this wealth of information using MQTT / MQTTS, HTTP / HTTPS, and JSON Parse/Build instructions.

BRX controllers’ Rest API also provides easy integration with corporate-level IT systems so plant-floor data can be compiled and analyzed with data from other departments, like procurement or logistics, for a bird’s eye view of the complete production process, from start-to finish.

10. Fortified with American pride

The BRX PLC hardware is built to last and is engineered, manufactured and supported right here in America by industrial automation veterans. With hardware design and fabrication facilities located in Tennessee and Florida, the BRX PLC platform delivers the quality you expect but at a price you won’t.

But that’s just half of the story!

The FREE Do-more Designer programming software was developed and is also supported in the US by expert developers with years of experience at the Host Engineering facility in Jonesborough, Tennessee.

![]()

https://www.automationdirect.com/do-more/brx/features