Three Trends That Will Make Functional Safety More Adaptable

November 30, 2020

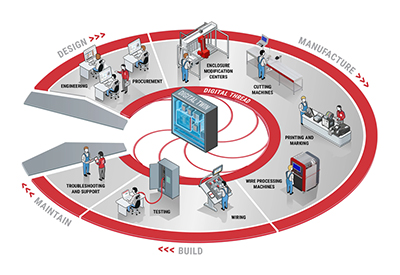

Flexibility is one of the most sought-after qualities in manufacturing systems this year. In recent years, manufacturers and automation suppliers have found that they could simultaneously increase flexibility and reduce costs by moving from a safety-by-wire solution to a safety network, adopting an approach dubbed “integrated safety.”

The concept of integrated safety became mainstream for OEMs and end-users just within the past year or so. By promoting a holistic approach that simplifies machine design, shortens commissioning time, and enables greater flexibility in reconfiguring production lines, integrated safety has quickly proven its value.

The future of integrated safety

As end-users discover how a single integrated development environment for safety and a safety network helps minimize costs for maintenance, setup and training, people have become curious about where this strategy is headed in the near future. We spoke with Todd Mason-Darnell, Omron’s Marketing Manager for Services and Safety, to get his perspective.

Todd highlighted three major trends for which integrated safety solutions will be an enabling component with respect to its ability to empower production and maintenance teams to make functional safety more adaptable:

1. Intelligent safety

As functional safety becomes a part of Internet of Things (IoT), digitalization and visualization initiatives, we’ll start seeing how the safety network can feed data not only for traditional big data uses, such as predictive maintenance and overall equipment effectiveness (OEE), but also to support visualization applications that help keep personnel safe from hazardous motion.

2. Interactive safety

The development of a common safety platform will make it possible for maintenance teams to monitor and diagnose events from different vendors over a single network. This reduces the amount of work required for integration, simplifies machine design and ensures safe operation of equipment.

The interactive safety concept refers to eliminating or reducing the need for dedicated diagnostic and troubleshooting tools, which in turn makes safety easier to maintain. You can do a complete system restore, replace damaged modules, or check the safety signature without using a laptop (which would have been necessary with other vendors or with Omron in the past).

3. Collaborative safety for fenceless solutions

We’re likely to see integrated safety become an essential component for adaptive collaborative applications that leverage safety sensor data, machine reaction times and safe motion functions. The purpose of these applications will be to keep operators safe without using traditional hard guarding or fixed hazard zones.

![]()

https://automation.omron.com/en/us/blog/integrated-safety-trends-2020