PTC and Rockwell Automation Extend Strategic Alliance

November 2, 2020

Having already helped almost 250 new customers around the world to achieve their digital transformation goals, PTC and Rockwell Automation recently announced the expansion and early extension of their strategic alliance.

This extension will ensure continuity in both companies’ sales and product development efforts and expand the agreement to include PTC’s product lifecycle management and software as a service (SaaS) products. This expansion will streamline both companies’ commercial efforts to extend a comprehensive digital thread solution, from upfront design through the operate, maintain and optimize-lifecycle stages. PTC will also offer Rockwell Automation’s virtual machinery simulation and testing software to its own customer and partner network. Under the agreement, both organizations will continue to leverage each other’s resources, technologies, industry expertise, and market presence to seamlessly serve their customers through 2023 and beyond.

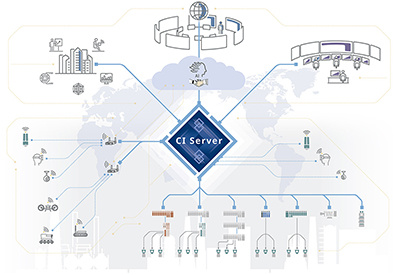

The companies’ primary joint offering, FactoryTalk InnovationSuite, powered by PTC,is the industry’s first comprehensive digital transformation software suite that offers fully integrated Industrial Internet of Things (IIoT), edge-to-cloud analytics, manufacturing execution systems (MES), and augmented reality (AR) – required for the connected enterprise. FactoryTalk InnovationSuite makes it simple to rapidly develop, operationalize, and globally scale innovative solutions to operations.

“Our selection of FactoryTalk InnovationSuite, powered by PTC could not have come at a better time for our company,” said Teja Schubert, Director, Controls, Automation and Technology, Norbord, an international producer of wood-based panels. “As the first wave of COVID-19 hit, it became even more important to have a platform that helps us reduce costs, improve our employee’s experience, and make better use of our maintenance and training efforts. This ever-important alliance has made it easier for our company to navigate the COVID-19 pandemic so far, and we look forward to leveraging future solutions.”

As manufacturers reset their operations, competitive pressures and demands for better financial performance have accelerated the need to digitally transform products, processes, and people across all business levels. PTC and Rockwell Automation’s industry-leading digital manufacturing solutions provide manufacturers with robust end-to-end digital thread capabilities, empowering them to continue their digital transformation initiatives amid the global pandemic.

“Over the past two years, PTC and Rockwell Automation teams have combined great innovation to offer our customers the world-class FactoryTalk InnovationSuite solution,” said Blake Moret, chairman and CEO, Rockwell Automation. “The expansion and early extension of our contract with PTC signifies the increasing value of this strategic alliance and its importance to the Connected Enterprise.”

Jim Heppelmann, president and CEO, PTC, said: “The strategic alliance with Rockwell Automation has expanded our reach and our capabilities as we champion Industry 4.0 initiatives around the world. The powerful impact of our offerings amid the current macroeconomic environment proves the market’s need for this collaboration.”

![]()