Industrial Case Systems: Enclosures for IoT Devices

October 14, 2020

Phoenix Contact’s industrial case system (ICS) encloses OEM designs in traditional and emerging industrial applications that require control, monitoring, conditioning, regulation, conversion, and other important functionality. The integrated connectivity in this ICS includes Phoenix Contact’s standard PCB mount and through-panel connectors, as well as other standard connections such as RJ45, DSUB, USB, and antennas. This enclosure system features complete connection flexibility, completely modular in its design. The ICS product line expands to 50 mm wide variants.

Customizable heatsinks can be combined and fully integrated into the ICS 50. Passive heatsinks, as part of the ICS series, enable the finished devices to be used in thermally demanding applications. Free online thermal simulations from Phoenix Contact allow customers to optimize their PCB layouts for proper heat dissipation. If a design requires detailed analysis beyond the online simulations, additional consultation is available with comprehensive, application-specific thermal simulations and suggestions. This provides a way to identify potential long-term failures at an early stage so that appropriate steps can be taken to prevent them. This supports the move to miniaturization and dense packaging of electronics, which results in higher operating temperatures.

Until now, packaging and hardware suppliers for industrial electronics left it up to an OEM to solve these thermal management challenges in designing devices. Phoenix Contact’s ICS portfolio and online services bridge the gap and will aid OEMs in bringing their devices to market quickly and efficiently. To recap, the three elements of this ICS include integrated cooling elements (ICE)/heatsinks, free web-based thermal simulation using the online configurator, and extensive thermal simulation as a consulting service.

![]()

Features

- – Integrated heatsinks (ICE) allow the ICS to be used in thermally demanding applications without complicated coordination with 3rd party suppliers or modification of the enclosure

- – Free online thermal simulations for up to three hotspots:

- – Facilitates optimum arrangement of components on the PCB and generates proposals, if needed, that include the use of passive cooling from venting and heatsinks providing added value and protection at no cost to the customer

- – Customized heatsinks based on hot spots and more sensitive components:

- – This is all done by Phoenix Contact – the thermal simulation, integrated heatsink, and modifying those heatsinks to accommodate each component, eliminating reliance on outside suppliers to provide the customer with a plan and product ensuring reliable heat dissipation for any application and requirement

- – Streamlined engineering design process as a one-stop shop for enclosure hardware:

- – Eliminates the need for customers to invest significant engineering/design effort into connectivity, thermal management, branding, packaging, functionality, etc.

- – Standard interfaces such as RJ45, USB, D-SUB, and antennas:

- – Easy integration and seamless design

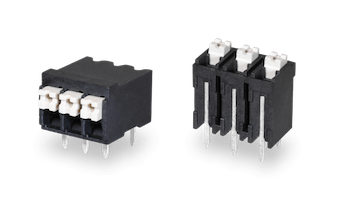

- – PCB terminal blocks and connectors with screw or push-in termination:

- – High applicability for different markets and applications

- – Modular system kit with various form factors:

- – Superior flexibility in the device design

- – Various customization options in design, color, and printing:

- – Highly individualized devices in a consistent brand design

Applications

- – I/O modules

- – Controls

- – Power supplies

- – Energy storage systems

- – Amps/repeaters

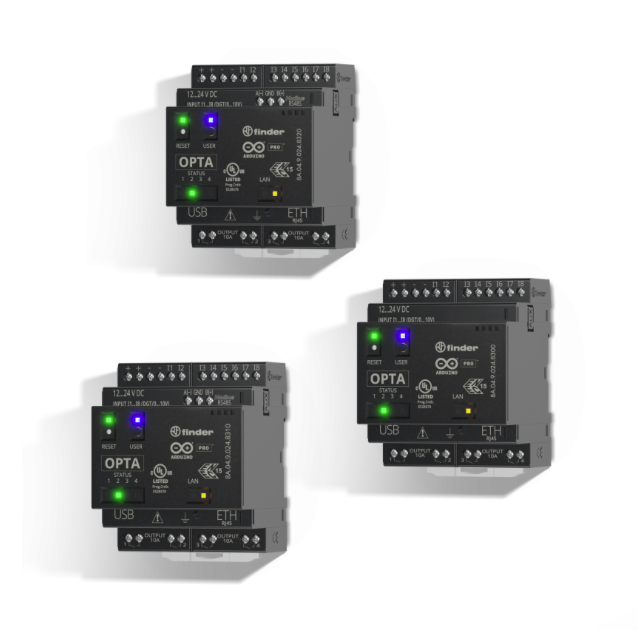

- – Communications devices: specifically edge and gateway devices for IIoT

![]()