Eaton’s New GFX Machine Dynamics Sensor Delivers Motion, Position and Navigational Sensing From One Compact Device

August 31, 2020

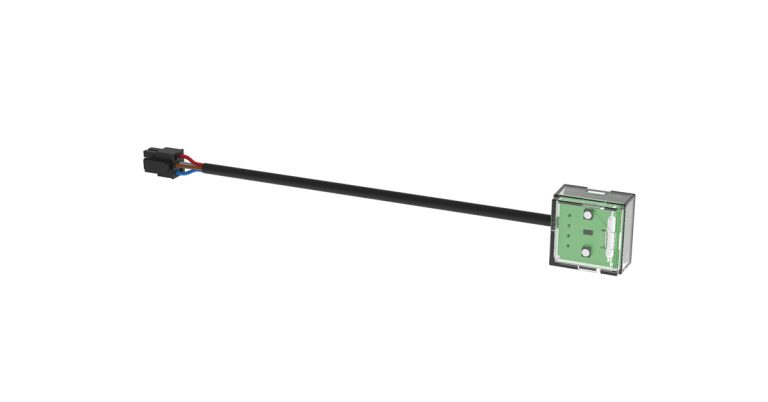

Power management company Eaton today announced the launch of its GFX machine dynamics sensor, a two-in-one device combining the functionality of a global positioning system (GPS) and an inertial measurement unit (IMU) in one compact package. With the ability to monitor machine location, speed, acceleration, direction, tilt, pitch and roll, the GFX device can help keep operators and their machinery safe and productive.

The GFX device monitors machine dynamics data that can be used to help maintain safe vehicle operation and maximize efficiency. For example, the acceleration, angular rate and magnetic field data can help avoid rollover accidents on uneven terrain, while true ground speed data and geopositioning can help optimize operations such as seeding, harvesting and earthmoving.

“As off-highway machinery becomes smarter and more dynamic, the need to track vehicle performance and equipment usage is only growing,” said Brent Schenk, global product manager, Dynamic Machine Control, Hydraulics Group, Eaton. “The GFX machine dynamics sensor provides added intelligence to help users operate their machinery safely and more efficiently while enabling better control of intelligent machine functions.”

As a two-in-one device, the GFX eliminates the need to source and integrate multiple components. It also offers space and cost savings over the separate devices that would be needed to perform the same functions.

With a wide operating temperature range of -40°C to 85°C, the GFX machine dynamics sensor is ideal for the rugged environments in which off-highway equipment operates. The device also features a dustproof and waterproof design rated to IP67, making it suitable for open-cab machinery.

![]()