U of M and Digi-Key Work To Design Cheaper Hospital Ventilator

April 17, 2020

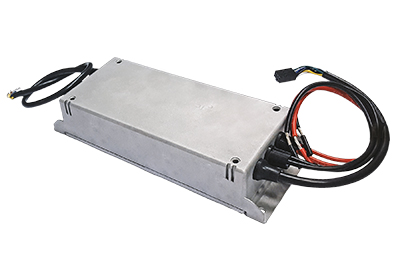

The University of Minnesota and Digi-Key Electronics have collaborated to rapidly design and make available a simple ventilator that can be quickly and inexpensively manufactured to aid coronavirus patients. Named Coventor, this device represents a rapidly scalable opportunity for healthcare providers to provide life-sustaining mechanical ventilation to patients for whom no other option currently exists. This mechanical ventilator is simple to use for ICU-trained medical providers. It is compact—the size of a cereal box—and relatively inexpensive to manufacture and distribute. This device does not require pressurized oxygen or air supply unlike commercially available mechanical ventilators.

The proposed system consists of a frame and mechanical actuator that will stabilize and compress a commercially available ambulatory ventilation bag connected to the patient’s endotracheal tube and external compressed oxygen, or if oxygen is not available, ambient air. The frame can be metal-stamped, 3D-printed or modified consumer goods.

University of Minnesota Anesthesiology fellow, Dr. Steve Richardson, started developing a cost-efficient patient ventilator in mid-March by researching a 1950s-era textbook and sourcing equipment and resources from biomedical engineer friends and other private companies like Digi-Key.

“The reason that we’re here today is that somebody needed this ventilator that we’re making, yesterday,” University of Minnesota anesthesiologist Dr. Stephen Richardson said in a video created by the research team. “This allows those patients who would otherwise not have an opportunity to survive, to survive. It gives people a chance.”

Digi-Key is an ideal partner with its significant inventory and just-in-time delivery capabiltiites.

“We’re told that we could need tens of thousands of respirators. And so that is going to be a real challenge,” said Randall Restle, vice president of applications engineering at Digi-Key. “We hope by the end of the week that we can have hundreds. And we’d like to finish the design in order to have thousands of tens of thousands made next week.”

Dr. Steve Richardson and the University of Minnesota are looking for production partners, specifically related to ambu bags, pressure relief (APL) valves, sheet metal fabrication (laser or water jet) and supplier/manufacturer of ball joint rod ends. Click Become a Partner to join the cause and assist in these specific areas of need.

![]()

More information on the Coventor ventilator

More information on Digi-Key’s involvement