Remee Wire & Cable Expands Custom-Made Cable Offerings with Unique Composite Constructions

February 11, 2020

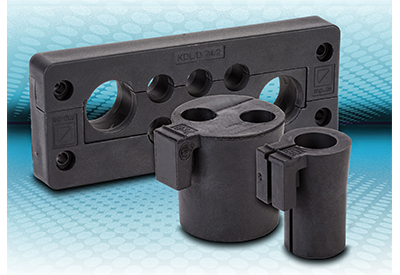

Remee Wire & Cable, a high-integrity manufacturer of electronic wire and cable for reliable performance, recently announced new custom design and manufacturing capabilities for cable products. Known for its breadth of capabilities and service to accommodate the manufacture of custom cable designs, Remee has recently added capabilities to make hybrid composite constructions with fiber optic and copper cable under one jacket. In addition, the company expanded its insulation and jacket compound offerings to include cross-linked polyethylene (XLPE) and Zero Halogen.

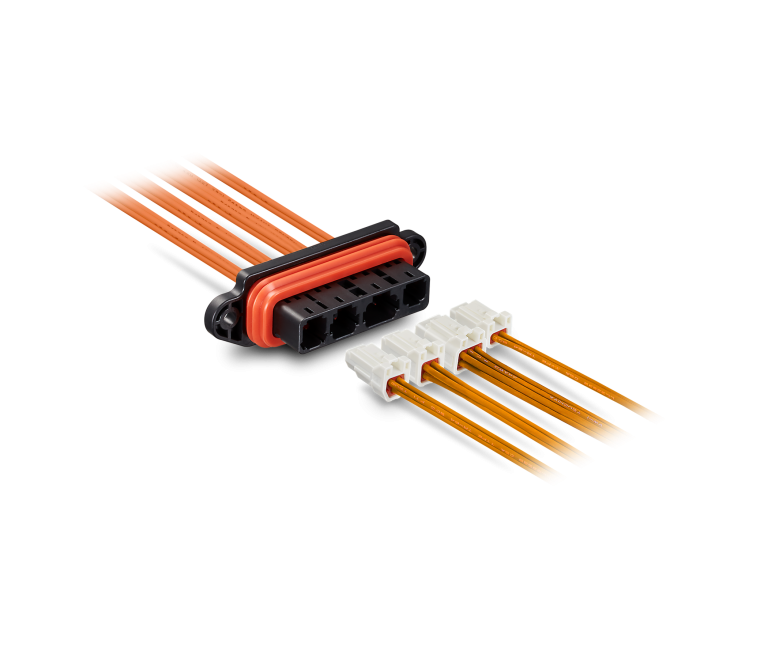

The hybrid composite cables are becoming very popular due to their ability to extend distances for data and power cable runs beyond the standard limits of PoE cables (100 meters or 328 feet). The flexibility of running longer distances and the cost savings associated with needing fewer or no electrical power outlets are the key benefits driving the growth in demand for these cables.

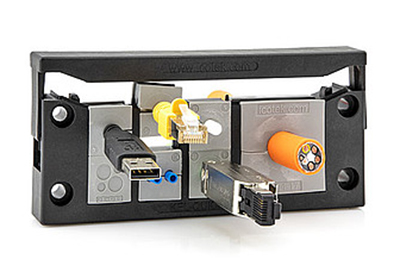

Remee responded to this demand with their new Activate Powered Cable Solutions, a series of composite and Siamese fiber and copper cable constructions. Remee is unique among cable manufacturers with its offering of these alternative powered cable solutions in a number of ways.

- 1. Remee manufactures its fiber tubes, with offerings using gel-filled and dry tube technologies.

- 2. Remee is expert in the use of both braid and foil shields for copper cables.

- 3. Remee uses only real solid copper conductors, unlike the many manufacturers who are diluting copper material for cost savings. Adulterated copper means poor signal integrity.

- 4. Remee has been manufacturing fiber optic cable for over 30 years and has extensive engineering and manufacturing expertise in the use of optical fiber.

- 5. Unlike larger cable companies, Remee manufactures the complete composite cables in-house, providing greater control over quality and lead time.

- 6. Most importantly, Remee knows how each of these above factors affect each other and impact the overall performance of the composite cable. Remee is expert in the art of the finely tuned composite cable.

Remee will partner with customers on non-recurring expenses (NRE) associated with listings, ratings and other 3rd party testing needed for custom projects. In addition to the many standards and approvals Remee has today, they are willing to obtain certain required approvals when needed, such as special AWM listings, depending on the order. Other listings that can be obtained include:

- – Burn Ratings

- – Torsion

- – Crush

- – Water Saturation

- – Temperature

When it comes to custom cable designs and custom-manufactured cables, no job is too small or too large for Remee. Their equipment, capacity and experience combine to provide the confidence customers need for reliable cable performance with a custom solution.

![]()

https://remee.com/capabilities/custom-made-cables/

https://remee.com/lan-premise-cables/activate-powered-cable-solutions/