Laird Thermal Systems Expands SuperCool Series

December 26, 2019

Laird Thermal Systems has expanded its space-saving SuperCool Series. The Peltier cooler assemblies are designed for applications that require high cooling capacities in tight space constraints such as chambers in medical diagnostics and sample storage compartments in analytical instrumentation. The smaller, refrigerant-free thermoelectric assemblies provide an environmentally friendly alternative to compressor-based systems for precise temperature control.

The new SuperCool Series provides engineers with three heat transfer options on the control side. Heat can be absorbed via liquid, conduction or convection. The Liquid to Air unit is only 230 mm x 150 mm x 109 mm and offers a cooling capacity of 140 Watts. The Direct to Air model is only 230 mm x 123 mm x 103 mm and has a cooling capacity of 130 Watts and the Air to Air unit is 230 mm x 150 mm x 156 mm with a capacity of 110 Watts. All cooling capacities are measured at ΔT=0°C and operate on a nominal voltage of 24 VDC. Custom configurations are available upon request.

Recent government regulations on the use of traditional and natural refrigerants critical to compressor-based systems make Peltier Cooling an appealing substitute. The compact SuperCool Series Peltier assemblies do not use refrigerants. Instead, the SuperCool Series has a unique hot side air heat sink design that dissipates heat more efficiently than conventional heat exchanger technologies. It uses customized Peltier modules that were specifically optimized to dissipate heat thru the high-performance heat exchanger assembly. The expanded SuperCool Series transfers heat to air more rapidly and is also quieter than previous models. Moisture resistant insulation and proprietary barrier seal protection is used to keep condensation from penetrating into the thermoelectric cavity for applications that go below dew point.

“Customers are requesting higher performance in smaller form factors. The SuperCool Series is designed to boost performance in medical and analytical instrumentation where space is a premium.” said Andrew Dereka, Product Director at Laird Thermal Systems. “The environmentally friendly SuperCool Series can also be considered as a substitute technology for compressor-based systems where government regulations are mandating OEM’s move away from hazardous refrigerants that deplete ozone.”

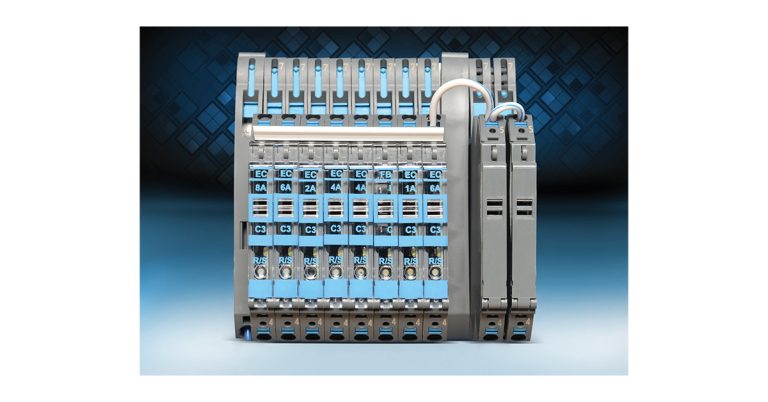

Combining a SuperCool thermoelectric assembly with a temperature controller offers significant design advantages over traditional technologies. The SR-54 programmable microcontroller provides thermal stability to within ±0.13°C of the set point in both heating and cooling modes. Its monitoring capabilities track potential issues, including problematic fans, thermoelectric modules, and thermostats for quick fault troubleshooting, maximizing uptime. Variable fan speed reduces operational noise and lowers power consumption.

The PR-59 temperature controller has precise temperature control and is configurable by end user with easy-to-use software from Laird Thermal Systems. In addition to temperature control, engineers can set additional parameters for fans, NTC thermistors, alarm and LEDs and monitor in real time.

![]()

- High performance

- Compact form factor

- Reliable solid-state operation

- RoHS-compliant

![]()

More information on the SuperCool Series Peltier cooler assembly

More information on Laird Thermal Systems temperature controllers