Eplan: The Digital Twin Lives

December 11, 2019

The future is digital. Panel building and switchgear manufacturing is no exception. Rittal and EPLAN have presented innovative developments under the heading of “Digital Information Management.” In the first step, the sister companies will be presenting the wiring plan pocket. During maintenance, service or repair work, it can be called up directly at the control and switchgear via a tablet.

QR code on the enclosure

The assignment between the digital documentation and the real enclosure is carried out via a unique and patented component QR code on the enclosure: in this form, a unique identification system that is assigned to every Rittal VX25 large enclosure and every AX\KX compact and small enclosure at the factory and which provides unique worldwide identification for every enclosure. The QR code can be scanned via a Rittal product scan app, for instance to obtain information on switchgear enclosure articles or, via the future Rittal Digital Information Management solution to view the EPLAN project associated with the enclosure or the machine.

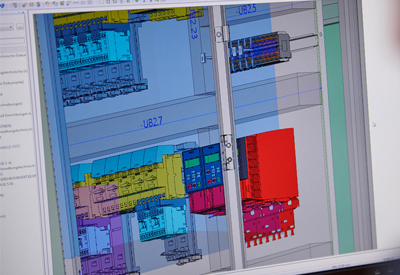

Using the “red-lining” function, the technician makes changes to the circuit diagram documentation via EPLAN eVIEW, a cloud service that connects to a version of the circuit diagram that is always up-to-date. The changes can then be taken over by the EPLAN project of the platform of the same name. This represents a major stage in panel building and switchgear manufacturing, where the circuit diagram and accompanying documents have been traditionally stored in paper form in the enclosure.

The cloud offers more potential

With a cloud solution, it is easy to connect to business processes within the company. For instance, if required, the service technician can directly trigger the online ordering of an essential spare part, including connection to warehouse logistics or purchasing. Such a solution can also be used to bill service calls, if they are carried out by external companies for example. If an existing control and switchgear system is to be modified or extended, the planners can carry this out directly based on the digital twin’s data. This way, inefficient duplicate work can be effectively avoided. These are just a few examples of how the former digital product twin can be reused as a digital operational or performance twin after delivery. Dr Thomas Steffen, Managing Director Research and Development at Rittal, explained: “Such Smart Services offer plant operators real added value in the operation of their plant, and this provides competitive advantages result for the panel builder and switchgear manufacturer.”

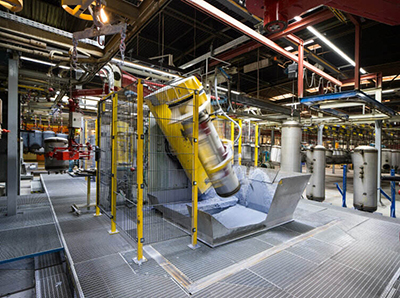

High data quality is the prerequisite

With the applications described above, the digital twin created during the planning and manufacture of a control and switchgear system also remains in use during operation. The basis for this is the careful handling of the data generated. Only comprehensive electrical planning and complete 3D construction planning can ensure that a digital twin of the system is created that contains all the details. It is important that high-quality data is available for all the components and systems used. Rittal is a pioneer in this respect; for every new system that comes onto the market, such as the VX25 enclosure or the AX and KX compact and small enclosures, the company provides both EPLAN macros and 3D design data. With consistent data management along the entire value chain, not only do control and switchgear manufacturers optimise their own processes, they also provide the customer with the digital twin of the plant, which permits additional services with real added value during operation.

Outlook:

This is the first step towards comprehensive solutions based on new cloud technology and with the objective of comprehensively streamlining the manufacturing process. Digital Information Management becomes a point of entry via cloud technology, which initially refers to the circuit diagram but which can also consequently communicate with neutral systems. At the SPS trade show, Rittal and EPLAN will be exchanging further ideas with manufacturers and customers.